Ultrasonic Reciprocating Spray Fluxing System

- Category: Fluxing Systems for Wave Solder Machines

- Manufacturer: Sonotek

An economical reciprocating ultrasonic spray fluxing system for medium to high mix lines. Easy integration and operation with all major wave solder machines. All SonoFlux systems feature non-clogging, repeatable, low maintenance ultrasonic spray performance with up to 80% reduction in flux consumption.

About the Ultrasonic Reciprocating Spray Fluxing System

The SonoFlux EZ system can either be installed internally in your wave solder machine or is available as a stand-alone unit. The system is also equipped with a high impact flux transfer system to help with PCBs that have difficulty with top-side fill, such as those with thick back planes, tight lead-to-hole ratios, or contaminated components.

INDUSTRY PROVEN - Sono-Tek spray fluxing systems with an non-clogging ultrasonic nozzle and spray dispensing mechanism have been proven in thousands of industrial PCB fluxing applications worldwide.

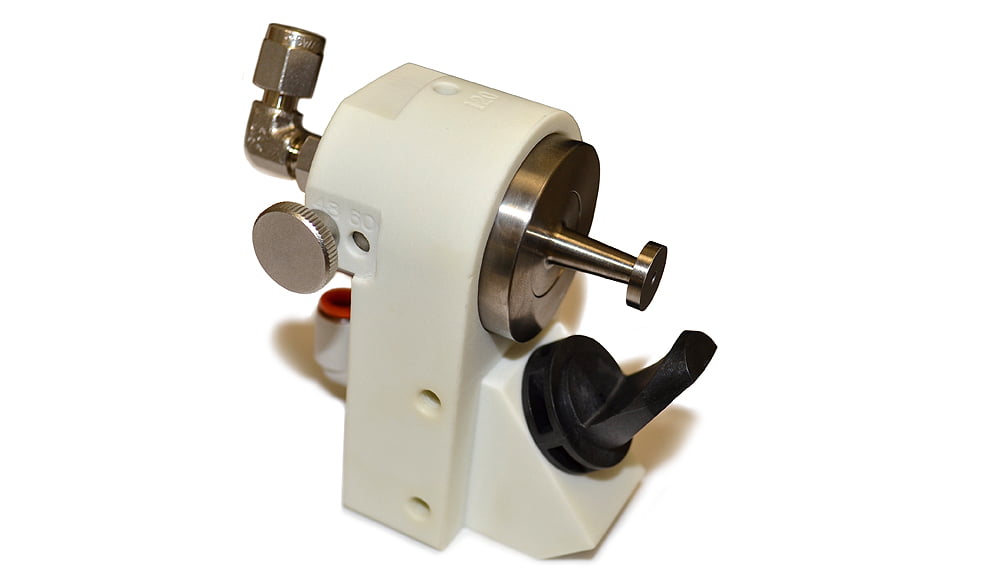

FLUX APPLICATION - Flux is supplied from a closed pressure reservoir to the ultrasonic nozzle. The flux reservoir includes a level sensor to alert the operator to a low level flux condition. The flux is atomized into a fine mist at the tip of the non-clogging, large-orifice ultrasonic nozzle which is reciprocated below the PCB, directing flux upward.

FASTEST PAYBACK - In many installations, Sono-Tek systems have a reduced flux consumption by up to 80% as well as reducing solder defects by a similar percentage. Compared to foam fluxing, additional savings are achieved by the elimination of thinner and titration checks, as well as reduced waste disposal costs. Sono-Tex systems have also been shown to reduce flux consumption by up to 50% when compared to conventional spray fluxers.

Features

- Economical reciprocating fluxer

- Easy integration and operation with all wave solder machines

- Non-clogging ultrasonic atomizing nozzle

- High velocity flux transfer for maximum top-side fill

- Low maintenance design reciprocator

- Uniform coverage

- Reduction in flux consumption up to 80%

- Compatibility with all fluxes

Basic Specifications

| Reciprocator Dimensions: 860mm W x 190mm H x 280mm D (34” W x 7.5” H x11” D) |

| PCB Width Range: 50-457 mm (2–18”) |

| Control: PLC with LCD Screen |

| Flux delivery: Pressurized flux tank |

| Power Requirements: 110/120 VAC, 50/60 Hz or 220/240 VAC, 50/60 Hz, Single phase, 900 VA max |

| Air: 344.7-689.5 kPa (50-100 PSI) @ 170LPM (6 CFM) |

| Motors: Stepper motor with belt drive |

| Certification: CE |

| Ultrasonic Nozzle Designs: Impact Flux head for maximum top side fill |

OPTIONS:

| External enclosure and conveyor |