Failure Analysis Services

- Failure Analysis (Board-and Component-Level)

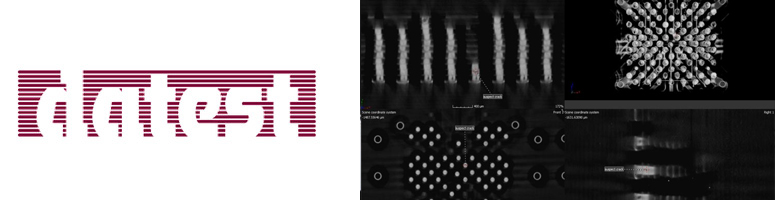

- Identification and Isolation of Microcracks

- Analysis and Measurement of Voids in BGAs, CGAs, QFNs, CSPs, LGAs, etc.

- Inspection of Solder Joints for Opens, Shorts, Excess and Insufficient Solder, and Missing Components

- Identifying Head-In-Pillow (HiP) Defects

- Isolation and Inspection of Package-on-Package (PoP) Defects

- Analysis of Connector Cracking and Other Defects

- Examination of Individual Board Layers

- Counterfeit Component Detection

- Production, NPI, and One-Board (“One Off”) Applications

Datest’s failure analysis services are a direct outgrowth of our over 30 years of electrical testing experience. We are very proficient at troubleshooting failed printed circuit board assemblies (PCBAs) and identifying root causes of failure. When a customer pays us to test their boards, they can rest assured we will do our level best to ascertain the causes of any failures, and not just pass those failures back without troubleshooting.

Since 2009 we have also offered nondestructive failure analysis services in the form of 2D and 3D xray, as well as digital tomographic imaging (CT Scanning). This is a quick-turnaround service, as our principal client is a process or quality engineer with a problem in need of an immediate solution. Turnarounds for most board-level projects are less than a week. We often take projects on a next-day or even same-day basis, workload permitting. We are quite capable of then producing a detailed report of findings (Hello, Military/Aerospace customers!), if that is required; however in most cases the customer is satisfied with obtaining the root cause of their problem in the form of detailed x-ray or CT images.

Frequent users of Datest’s failure analysis services often see value in placing blanket purchase orders with us, in order to speed access for multiple teams of engineers working on multiple independent projects. We are comfortable working with blanket orders as well as individual, project-specific purchase orders. We also accept credit cards from those customers who are new to our services and who wish to expedite a project without delay due a lengthy account setup process.

As we are lifelong printed circuit board test engineers, we are comfortable quoting a board-related failure analysis project from a description and a picture of the area of interest to be examined. If the project is non-PCBA related, we may need a sample or some additional detail about the areas of concern and the applicable failure modes and acceptance criteria. However if you are willing to invest the time with us, then we will invest the time with you, and hopefully make it worth your time, effort, and expense. We want you back as a satisfied customer. The best way to have you back is to consistently deliver results in a timely manner.

In addition to xray services, Datest, through its “ecosystem” of affiliated partners, offers many other nondestructive as well as destructive analytical laboratory services. Examples include cross-sectioning and dye & pry services as well as SEM, CSAM, and XRF analysis. If it isn’t under our roof, we probably have a close partner with a complementary service. We can introduce you to our partner or manage the process directly for you, depending upon the manner of proceeding most comfortable to you. Flexibility and speed in response time is the key to putting together a worthwhile failure analysis program. We offer a good track record in that regard.

If you have a problem calling for failure analysis, chances are we have a solution. You’ve come to the right place.

SW Systems is a Datest failure analysis services sales representative company that covers the states of Texas, Oklahoma, Arkansas and Louisiana.