Tracking Software for the PCBA Industry | 360° Traceability

- Category: PCBA Traceability

- Manufacturer: Cogiscan

Complete And Accurate Reporting Of The Entire Production Process

What used to be simply an insurance policy in case of a recall, traceability is now a must-have as it provides unparalleled insight into what exactly happens on your factory floor. The 360° Traceability Application offers fast and accurate product, material and process traceability to help you demonstrate the quality of your products to your customers.

About the Tracking Software for the PCBA Industry | 360° Traceability

CHALLENGE

Having a complete history of everything that happened to a product during production is no longer an option for today's electronics manufacturers. Since many customers today have strict auditing requirements, you need to deliver proof of the quality of the products you assemble. In order to meet these stringent requirements, you need reports with precise details of the entire manufacturing process.

SOLUTION

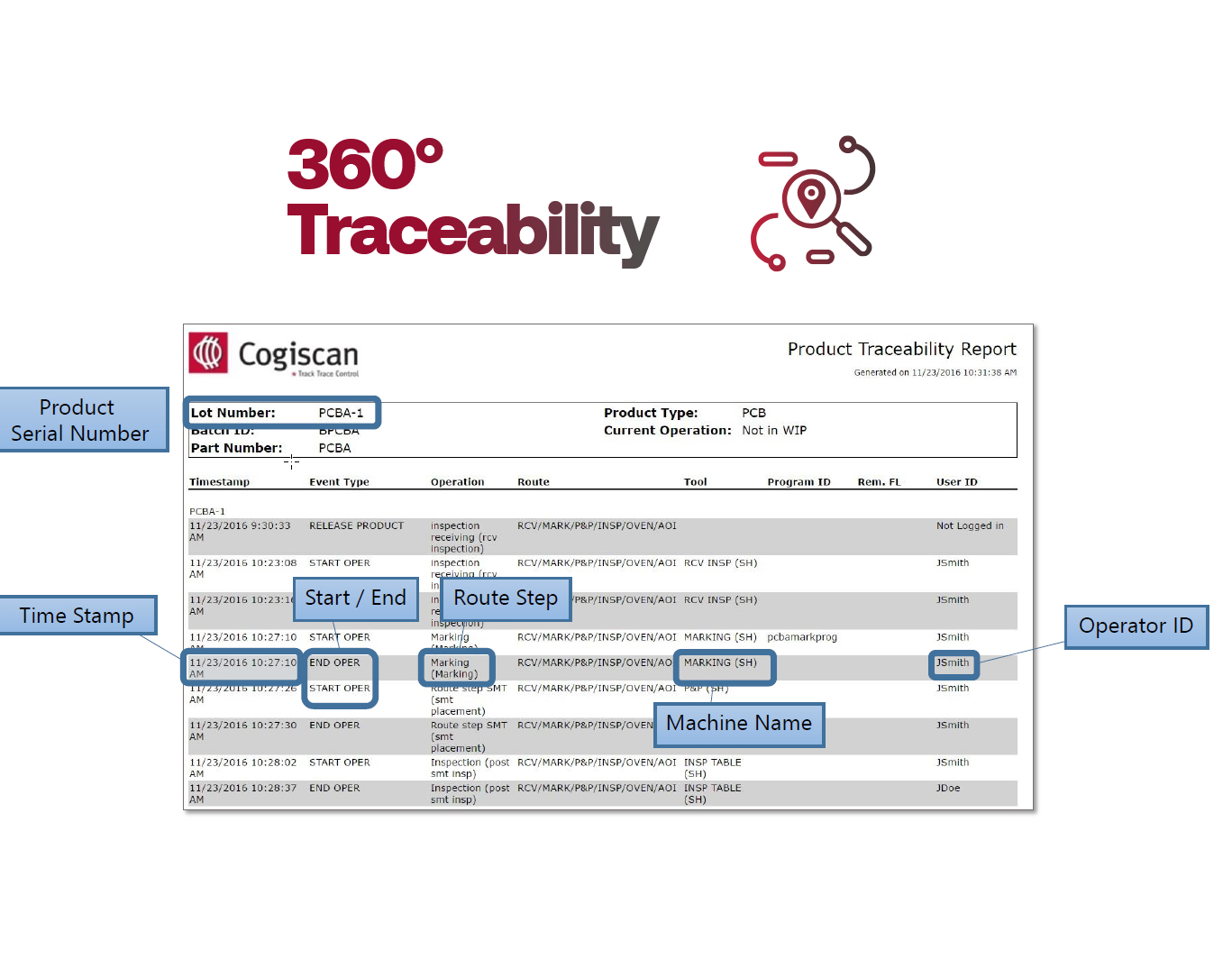

Our Traceability application equips you with complete and accurate material, product, and process reporting. Every element of the production process is recorded – who touched the product and when it was in process, what operations it went through and how that process transpired, what materials were used and where they came from – showing customers why they can trust in the quality produced. You can rest assured that you’ll have accurate traceability reporting for every PCBA you manufacture.

FEATURES

- Material Traceability - Tracks and records all materials used in the production process including components, consumables, and special tooling. Detailed information, such as supplier, lot code, date code, and MSD requirements are recorded for each product ID.

- Product Traceability - Records all product-level traceability for each board ID including product and work order information, start & end times for each operation, the type of operation, as well as available operator details.

- Process Traceability - Tracks and records all process-related settings and parameters. Includes detailed information such as program name, temperature settings, inspection results with defect codes, and measured test values.

- Rapid Reporting - Easy to use reporting feature allows users to quickly pull traceability records for individual products. Filters and optional drill-down features allow users to quickly identify all impacted products populated with suspect components.

- Configuration Options - The flexible installations of our solution means we can trace as much or as little of the production process as desired.

BENEFITS

- Facilitates Compliance - For quality stringent industries, such as medical (ISO 13485), automotive (TS 16949), and military (AS 9100), our traceability solution helps you meet their requirements.

- Simplifies Product Recalls - In the case of a recall, you can quickly identify impacted units in order to greatly reduce warranty costs and keep your brand reputation intact.

- Enables Smart Actions - Immediately identify the source and scope of a quality issue in order to take corrective actions right away.

- Searching Made Simple - Search for PCBAs populated with specific materials based on date code, lot, supplier, etc.

- Improves Satisfaction - Printable reports to share with clients detailing precisely what happened to a PCBA in production.