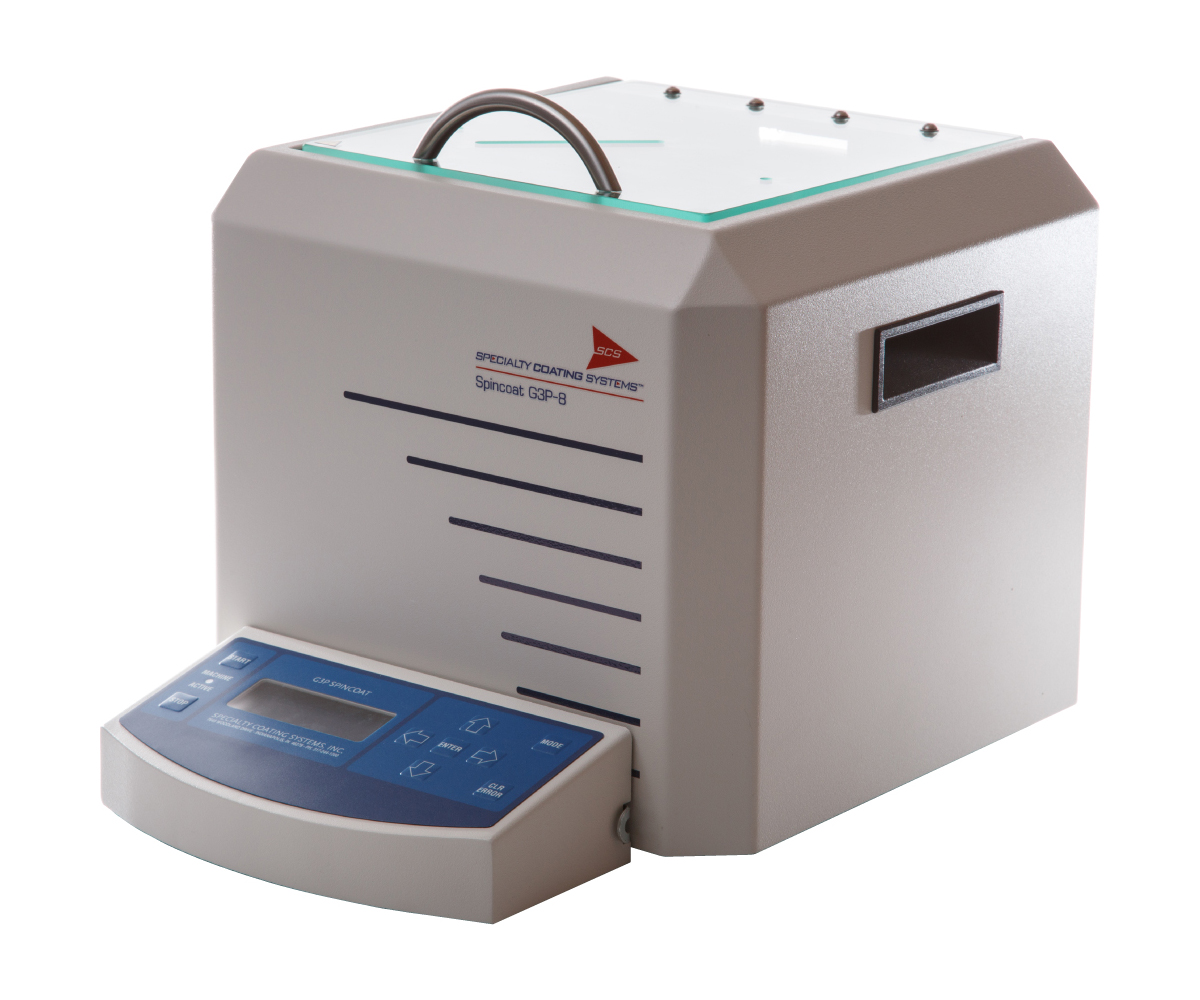

G3 Spin Coater

- Category: Spin Coaters

- Manufacturer: SCS

Compact yet packed with performance features, the SCS G3 Spin Coater series combines precision with control for highly effective coating applications development. Adding to its performance is a number of optional features.

About the G3 Spin Coater

The SCS G3 Spin Coater series sets the standard in operating precision and programming flexibility. It is engineered to provide a high level of rotation accuracy and repeatability, along with precise acceleration and deceleration control. The result is a spin coating solution that combines options to meet specific lab requirements with a level of performance that delivers confidence with every coating application.

Available with three different bowl sizes, SCS G3 Spin Coaters feature compact housing for convenience when using in fume hoods. Programmable spin coaters have an optional integrated dispense arm, optional exhaust adapter, and are equipped to control solenoid operation of an optional dispensing unit. SCS Spin Coaters are ideal for applying photoresists, polyimides, metal-organics, dopants and silica films on planar substrates.

- Compact enclosure size

- Available with 8, 12 and 15-inch bowls

- Fast, simple programming by means of microprocessor-based control

- Front flat panel LCD display and keypad

- Close loop servomotor for precise speed regulation

- Communication port for external control using optional PC interface software for programming, profile storage, PID, diagnostics, vacuum on/off, slow speed centering, and programmable house position.

- Stores and executes up to 30 programs, with up to 20 steps each (unlimited w/ optional software)

- Spin profiles adjustable in 1.0 rpm rotation increments, 0.1 second timing increments, and 1.0 second increments for dwell time.

- Precise repeatability from cycle to cycle

- Encoder allows vacuum chuck to be stopped at a Home position

- Chemically resistant Teflon coated bowl with integral drain

- Hinged, interlocking cover

- Safety glass window

Options

- PC interface software

- Bluetooth® wireless communication

- Foot pedal

- Fume exhaust adapter

- Manual dispense

- Automated dispense (SCS Multi-Dispense)

SCS MULTI-DISPENSE

An SCS G3 Spin Coater coupled with the SCS Multi-Dispense, enables research and development laboratories to easily and efficiently develop and refine coating applications for a variety of uses. The SCS Multi-Dispense enables users to dispense liquid materials to an SCS spin coater from up to four different dispense modules (three with the use of N2). Materials can include coatings, solvents and cleaning solutions in addition to N2 for blow-off or drying. The Multi-Dispense eliminates the need for time-consuming cleaning and change-over, while providing the accurate and controlled coatings you have come to expect from SCS.

VACUUM CHUCKS

Stainless steel and hard anodized aluminum accessory chucks are available for a variety of substrate types and dimensions. Chuck components are machined to close tolerances for flatness and rigidity and feature a cross pattern to distribute the vacuum across mounting surfaces. A chuck’s active surface must be entirely encompassed by the substrate. Fragile substrates should be supported across the entire surface.

Specifications

| Program Storage | Nonprogrammable Model: Single step profile Programmable Model: 30 programs, 20 steps each |

| Bowl Size | Nonprogrammable Model: 8 in / 20.3 cm Programmable Model: 8, 12 and 15 in / 20.3, 30.5 and 38.1 cm |

| Rotational Speed | Range: 0 to 9999 RPM in 1 RPM increments Tolerance: ±1 to 3 RPM full scale * 4000 RPM maximum for the 15-inch bowl unit. |

| Acceleration/Deceleration Time | Range: 0.1 to 25.5 seconds in 0.1 second increments Tolerance: ±0.05 seconds * Size and weight of substrate will affect acceleration values. |

| Dwell Time | Range: 0 to 999 seconds in 1 second increments Tolerance: ±0.05 seconds |

| Dispense Time (Optional feature) | Range: 0 to 25.5 seconds in 0.1 second increments Tolerance: ±0.05 seconds |

| Acceleration/Deceleration Linearity | Tolerance: ±%0.1 |

| Power Input | 115/230 VAC, 50/60 Hz, 1Ø |

| Vacuum Input | Minimum 17 in Hg / 430 mm Hg; O.D. Fitting: 0.25 in / 0.635 cm |

| Purge Input | 0.55 CFM at 5 psi / 14.15 CLM at 0.35 kg/cm2 Dry air or nitrogen |

| Dimensions (W x D x H) | Nonprogrammable Model, 8 in: 12 x 15.5 x 10.5 in / 30.5 x 39.4 x 26.7 cm Programmable Model, 8 in: 12 x 16.5 x 11.7 in / 30.5 x 41.9 x 29.7 cm Programmable Model, 12 in: 16 x 20.75 x 11.7 in / 40.6 x 52.7 x 29.7 cm Programmable Model, 15 in: 19 x 23.3 x 11.7 in / 48.3 x 59.2 x 29.7 cm |