Small Boards Selective Soldering Machine – MAS-i4

- Category: Mass Production Selective Soldering Machines

- Manufacturer: SASinno

The Highest Flexibility And Output For Small Boards Soldering

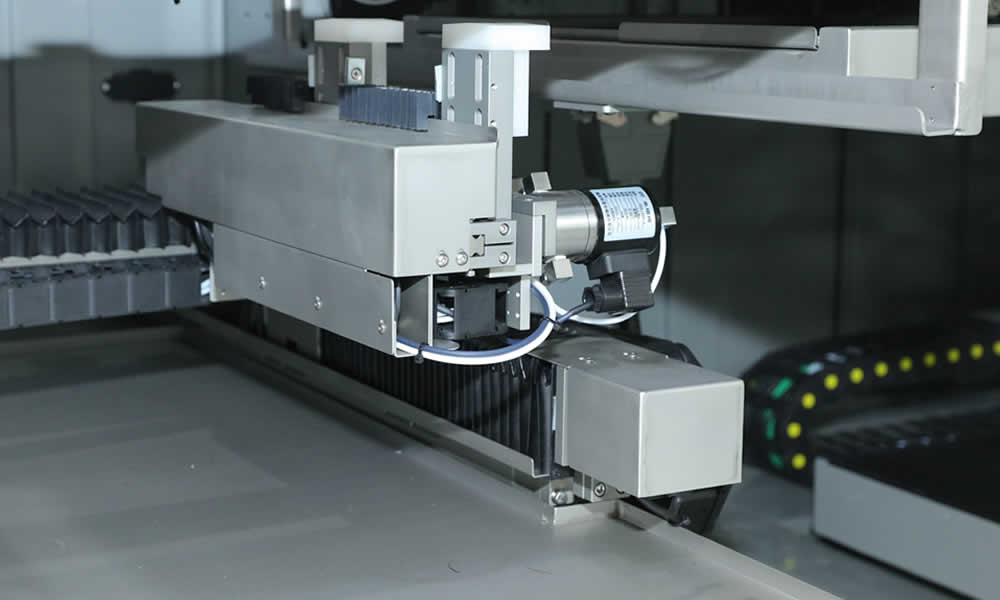

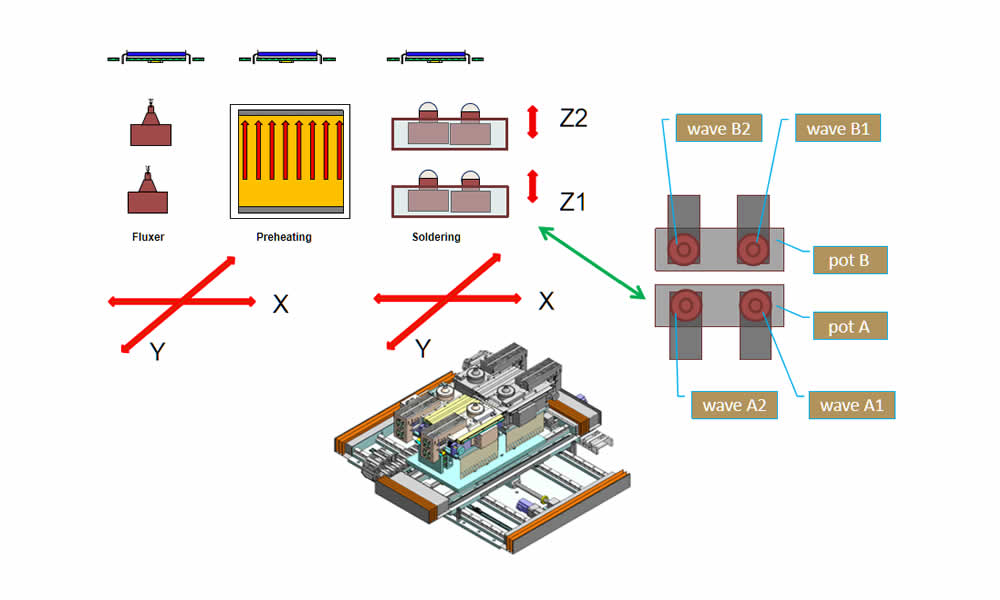

The latest generation selective soldering machine with the highest flexibility and output. The system features an XY servo table for two independent fluxer nozzles (fluxer 1 and fluxer 2). The distance between the fluxers is automatically adjusted by servo motors, as programmed by the software.

About the Small Boards Selective Soldering Machine – MAS-i4

Customers can choose to use only one fluxer for all boards so it can accommodate two flux types in one machine, or they can choose to use two fluxers with the same flux. For preheating, the MAS-i4 is equipped with a top convection preheating zone and bottom IR preheating zone. The top preheating zone is above the soldering section for better solder fill up.

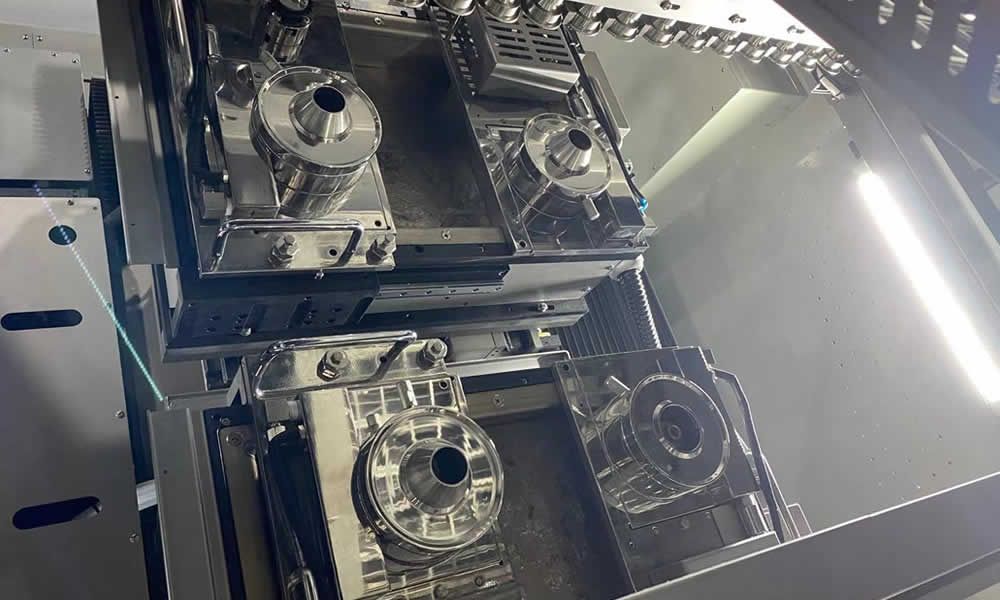

For the soldering section, MAS-i4 has dual individual solder pots in each Z axis. Each solder pot has dual individual selective wave tunnels. That means if a customer is looking for maximum production output, they can use the carrier for four pieces of the same board and they will be soldered at the same time. This means 4X the production compared to most competitor systems. Or, two nozzles can used – a large nozzle and two small nozzles to solder the same board with best flexibility.

- 2 drop jet fluxers as standard

- Bottom IR preheating & top preheating zone

- 2 solder pots in individual Z-axis, each with 2 wave tunnels

- 3 sections of conveyors

- Fixed PCB conveyor with moving solder pot/fluxer

- All-in-one flux, preheating & soldering

- Flux table with XY motion table, soldering table with X, Y, Z1, Z2 motion table

- Windows 10 system

- Standard equipped with wave height calibration

- Real-time soldering process monitor

Specifications

| Item | MAS-i4 |

| General | |

|---|---|

| Operating power/Max power | 8KW/25KW |

| Conveyor width | Max 510mm |

| PCB size | As explanation |

| PCB top clearance | 100mm |

| PCB bottom clearance | 35mm |

| Machine dimension | 3360(L)*1750(W)*1650(H) |

| Net weight | 1800KG |

| Power supply | 3PH 380V 50HZ |

| Air supply | 3-5 bars |

| Exhausting required | 800M3/h |

| PC | Yes |

| Typical Program Time | 10 Minutes |

| PCB Robotic Platform | |

| Flux Nozzle Type | drop jet fluxer made in Germany |

| Flux Nozzle Quantity | Standard equip 2 set |

| Flux Tank Capacity | 1L |

| Flux Tank Quantity | 2pcs |

| Flux Nozzle Distance | width adjustable by software |

| Axes of Motion | X, Y Servo motor |

| Position Accuracy | +/- 0.05mm |

| Preheat | |

| Preheating method | Top IR preheat,option with bottom preheat |

| Solder Management | |

| Solder pot type | Standard equipped mechanical pump |

| Solder pot quantity | 2 individual sets |

| Solder Pot Capacity | 30kgs/pot x 2pots |

| Solder Pot distance | 240mm--300mm software adjustment |

| Solder level alarm | standard equipped |

| Wave tunnel | 2set/pot x 2pots |

| Wave distance | 160--255mm manual adjustment |

| Mini Wave Nozzles | Dia 4, 6, 8, 10, 12MM |

| Customized nozzle | Available |

| Axes of Motion | Pot 1&2 share X, Y. Pot 1 with Z1, Pot 2 with Z2 |

| Motion Control | All servo control with ball screw |

| Position Accuracy | +/- 0.05mm |

| (N2) Inertion Management | |

| N2 Consumption per Nozzle | 1.5m3/H, total 6m3/H (recommend to use SELMATE-8) |

| Required N2 Purity | >99.99% |