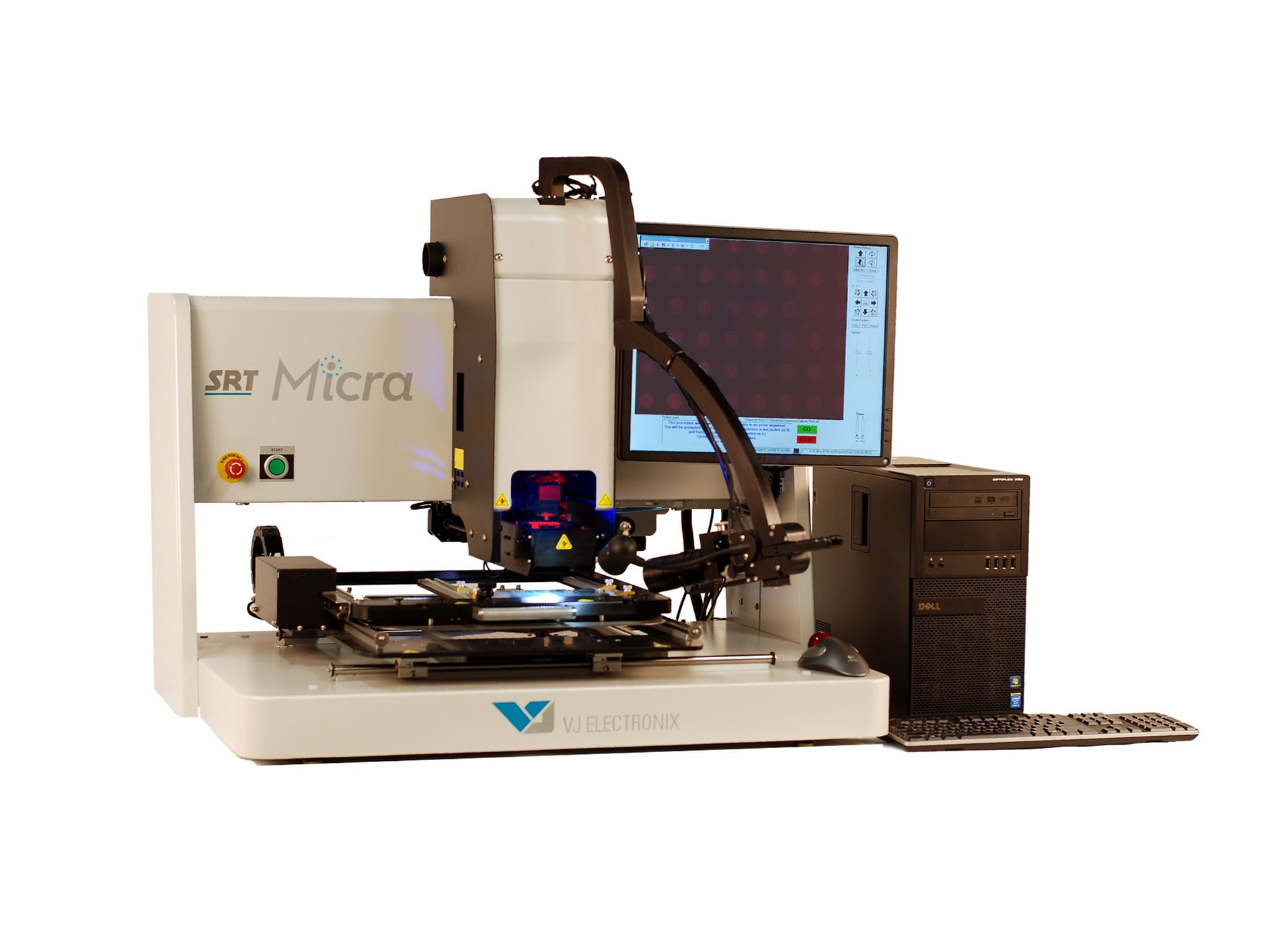

Semi-Automatic Bench-Top PCB Rework Station – Micra

- Category: PCB Rework Stations

- Manufacturer: VJ Electronix

High Precision, Bench-Top Rework System For Small PCBs and Components

About the Semi-Automatic Bench-Top PCB Rework Station – Micra

The Micra is best in class for small board that require high-precision.

- Maximum PCB Size: 300x350mm

- Maximum Field of View: 35mm

The popular Micra is designed for rework of smaller, high performance components, such as Chip Scale Packages (CSP), Package on Package (PoP), and Micro Passives (01005). The enhanced Micra provides a larger 35 mm alignment field of view, expanding its range of applications into more automotive, medical and military/aerospace products.

Built with easy-to-use 1-2-3-GO software, operation of this rework system is simple and intuitive. Efficient convection heating provides high thermal throughput, uniformity, and a repeatable rework process. Automatic non-contact site scavenging safely removes residual solder, eliminating potential for damage to pads and solder mask. Proprietary software provides product traceability, profile analysis, and sharing of profiles between VJE systems.

Micro Assembly Rework - The Micra addresses the challenges of reworking and scavenging the smallest and most tightly spaced technologies.

Independent Pick and Place - Motorized reflow head driven by an advanced motion system with programmable force control provides precision with total flexibility.

Nitrogen Inert Environment - Programmable process control applies nitrogen only when needed maximizing N2 savings.

Industry 4.0 Compliant - Automated data/event logging directly to your EMS. Enhanced profile sharing and user collaboration

Auto Profiling Capability - Fast and easy profile creation. Simply enter the desired product temperatures. After thermal profile is created, the entire reflow process is built automatically and ready to run.

Efficient Convection Heating - Closed-loop temperature control ensures a more even heat distribution as compared to IR heating.

Non-Contact Site Scavenging - Dynamic height sensing control of distance between the scavenger tip and PCB (scavenger gap). Eliminated risk of damaged pads and solder mask.

Easy-To-Use Auto Profiling Software

- User-friendly, simple thermal profile development

- Default reflow profiles for standard rework processes

- Advanced profile analysis software confirms successful profile development

- Automatic reflow, remove, and replace profile created after development of Auto Profile

Simple Component-to-Site Alignment

- Two-color LED optical alignment system allows for easy-to-see component to site alignment

- Motorized and programmable X and Y table

- Fully programmable motion allows for automatic rework (optional)

Repeatable Thermal Performance

- Efficient Convection Heaters provide high thermal uniformity

- Board conditioning (preheat) is temperature based via thermocouples allowing for precise temperature measurements

Automatic Non-Contact Site Scavenging

- Dynamic Height Sensing (DHS) Scavenger maintains consistent scavenger tip to board gap safely removing residual solder

- Programmable X,Y, and Z axis eliminates operator intervention

- Nitrogen capability for consistent results without post scavenge cleaning

MES Interface

- Track all operations performed on rework system from automatic event log

- Reflow processes easily transferred between systems

Available Tooling for Any Surface Mount Component

- Standard nozzles for conventional components

- Special nozzles for unique components

Specifications

- Placement Capability: 0.0005” (12u) mean + 3σ

- Maximum Board Size: 12” x 14” (300 x 350mm)

- Minimum Component Size: 01005

- Maximum Field of View: 1.4” (35mm) Square

- Thermocouple Jacks: 4 (8 optional)

- Theta Motion: 360°

- Top Heater: 1500W

- Site Heater: 800W

- Area Heater (option): 2400W