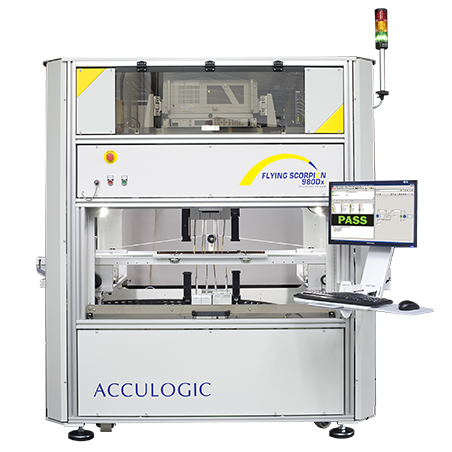

Flying Probe Tester – Scorpion FLS980Dxi

- Category: Flying Probe Testers

- Manufacturer: Acculogic

The Ultimate Probing Machine

Ultra Fast full Function Patented Double-sided, Closed Loop 22-probe System, All probes are Analog, Digital, Boundary Scan, and Vectorless Test enabled. Use it In-Line or manual operation with AOI capabilities.

About the Flying Probe Tester – Scorpion FLS980Dxi

The FLS980™ Series of Flying Probe testers, help ensure that tomorrow’s technologies don’t outpace today’s test capabilities. Acculogic’s production board test systems offer highly advanced, scalable solutions to solve a wide range of test challenges. Our automated test systems are made to accommodate a variety of applications and customers. We offer an unbeatable combination of reliability, accuracy, precision and throughput.

WHY YOU SHOULD CONSIDER THE FLS980 FLYING PROBE TESTER:

- Superior Test Access

- Exceptional Test Coverage

- Ultra High Accuracy

- Patented Multi-Probe System

- Power-On and Advance Function Testing

- Design Recreation Tool

- Test large boards

TEST ACCESS

Shrinking component sizes and denser chip scale packaging technologies are posing new challenges to test engineers. Test pads, traditionally installed on PCBs, are being eliminated from many designs thus reducing physical access. Flying Probers are required to operate with unprecedented precision in order to meet the new challenges.

The FLS980 Production Test Platform uses highly repeatable closed loop linear motor drives and joystick-like variable angle probe modules to maximize physical access and guarantee repeatable probing of fine pitch devices and small components. The FLS system offers double-sided probing and up to 24 probe modules on the component and solder side of the Unit Under Test (UUT) to facilitate efficient single pass testing.

ACCURACY

Due to its modular and scalable architecture, the FLS980 guarantees superior probing precision and repeatability. Precise Closed Loop planar linear motors (shuttles) with “AccuFast™ Drive System” (1 micron minimum step size, +/-10 micron positioning repeatability) independently move probe modules and cameras. The probe modules utilize equal-length identical probes to contact target points on the UUT. Each variable probe module is able to set the probing angle from 0º to 6º from vertical in any direction. The combination of shuttles’ positioning and joy-stick like probe motion ensures unmatched accessibility to points on the UUT. You can now test boards whose layout, size, and technology encumber traditional in-circuit testers and other flying probe testers.

The system architecture ensures repeatability:

- Closed Loop Drives for shuttles and probe modules ensure precise and repeatable positioning of the probes

- Riding on 20 micron air gap, shuttles travel free of friction and with no mechanical contact on the stator plane and therefore operate free of wear

- High resolution fiducial detection cameras, precise lighting, and advanced image processing software ensure precise and repeatable detection of fiducial marks on the UUT as well as correct compensation for any offsets

- LaserScan profiles board warpage

- Electronic measurement system relies on precision circuits and components for reliable and repeatable measurements

- Integrator™ system control software with sophisticated motion control and measurement algorithms ensures robust and repeatable operation.

PROBING ANGLE

Warping of printed circuit boards is a common issue that should be taken into account in SMT board assembly, inspection and test processes. During Flying Probe test, board warp changes the physical position of target points by an offset. When probing angle is 0 degrees from vertical, board warp will cause no probing errors, however, as the probing angle increases, the probing error also increases. A 0201 chip on a board with 0.5 mm warp using 15 degree probing angle cannot be probed dependably. Decreasing probing angle to 3 or 4 degrees reduces warp related uncertainty, and leads to reliable probing.

Offering optimum probing, FLS980’s Advance probe modules rely on a patented design to probe target boards Omni-directionally on the horizontal, and -6 to +6 degrees on the vertical planes. As probing angle increases the probe slippage factor increases. Probe slippage can lift pads and vias and leave unacceptable marks on the target.

THROUGHPUT

Test times on a Flying Probe system depends mainly on the number of test steps and speed of probe movement. Shorts Test consume a large part of overall test time. The FLS980’s flexible measurement system provides a host of test strategies including Boundary Scan (JTAG) and NetScan™ to significantly reduce test time without impacting test coverage or repeatability. In addition AccuFast™ Closed Loop Drive system boosts speed and acceleration by 4 times over open loop systems.

- Faster than open loop systems (1.5x)

- High acceleration (4x)

- Enhanced probing accuracy

- Three times better dynamic response +/- 1 degree rotation

- Automatic orthogonality between X and Y axis

- Sensorless homing (no adjustments)

- DSP based motor controller

- Built-in linear and parabolic interpolation (more efficient shuttle movements)

Boundary Scan (JTAG) testing can reduce the overall “shorts” and “opens” test time by up-to 80%.

PATENTED MULTI PROBE SYSTEM

The FLS system has a modular architecture that is expandable to 22 probes. The probe modules have easily interchangeable probe tips. A range of probe tip styles are available off the shelf. In addition to providing excellent test coverage on densely populated circuit boards, this flexibility makes the FLS980x an ideal solution for testing backplanes where direct contact with connector pin tips is required.

MEASUREMENT SYSTEM

FLS980’s high speed (up-to 1000 measurements/sec) analog measurement system provides 4-wire measurements capability on all 24 flying probes (top and bottom side). All probes can perform in-circuit tests as drivers, sensors, or guards on discrete and integrated analog/digital components. Analog component testing including resistors, capacitors, inductors, diodes, zeners, transistors, FETS, thyristors, opto-couplers, switches, trimmers, relays, fuses and connectors are standard on the FLS980.

Test modes include 2-wire, 4-wire tests (and the unique Quasi-4 Wire measurement using Only two test points). Device ON and OFF tests using two sets of separately available stimulus/measurement resources. Also, power-on testing for voltage regulators and operational amplifiers are possible using the voltage measurement module.