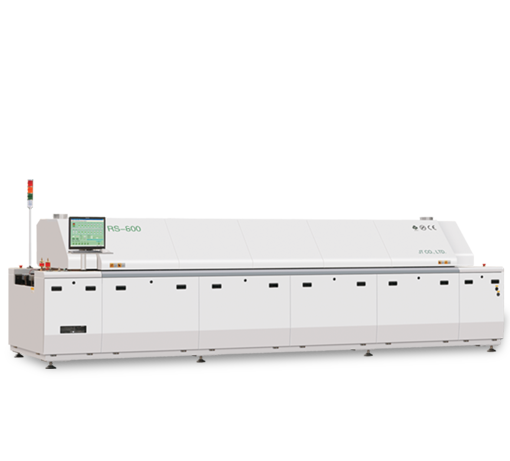

Hot Air / Nitrogen SMT Reflow Oven | JUKI RS-600 Six Zone

- Category: Reflow Ovens

- Manufacturer: juki

Lead Free, ECO Friendly Hot Air / Nitrogen Reflow Soldering Oven

The RS Ovens Efficient power design and air management system greatly improves energy savings while lowering carbon emissions.

- Independent Air Velocity Controlling System

- Cooling Configuration Recycles to reduce Thermal loss

- Efficient Power Design and Air Management System

- Every Machine Equipped with Industry Standard Features

About the Hot Air / Nitrogen SMT Reflow Oven | JUKI RS-600 Six Zone

JUKI's RS 600 6-zone reflow-soldering oven is the space-saving and inexpensive solution for the numerous standard SMT soldering tasks. Taking up a small amount of floor space and having low energy consumption, the machine has all the advantages of a larger reflow-soldering oven such as perfect thermal properties as well as comprehensive equipment including useful features.

- Inexpensive and space-saving.

- Very good thermal properties (∆T Crossprofile < ±2 °C).

- Low final consumption as well as a short warm-up period (25 minutes).

- Available also as a nitrogen oven.

- Soldering flux deposit due to a condensate trap, optional with nitrogen.

- Numerous useful functions already incorporated without extra charge.

- 3-year warranty on ventilators and heating elements.

SPECIFICATIONS:

Process Characteristics

- Number of Heating Zones 6

- Number of Cooling Zones 1

- Total heated length 2,340 mm

- Total cooled length 440 mm

- Temperature Range Heating Zones 20 – 300 °C

- Separate Top and Bottom control of temperature

- Blower Fan top and bottom

- Blower Fan frequency separately controllable in zones

- Warm-up time approx. 25 Min.

- Nitrogen Option optional

- External Water Cooling for flux residue standard with nitrogen ovens

- ∆T Crossprofile < ±2 °C

PCB handling and transport

- PCB-width min. 50 mm / max. 460 mm

- PCB space top 25 mm / bottom 30 mm

- Conveyor speed range 30 – 200 cm / min

- Transport of PCB on Mesh / Pin conveyor chain

- Centre Board Support optional

- Conveyor direction Righ-Left optional

Machine properties and dimensions

- Dimensions (L × W × H) 4,205 × 1,320 × 1,505 mm

- Weight 1,900 kg

PC and Software

- Operating System Windows 10

- Interfaces Ethernet, USB, SMEMA, Cogiscan IFSNx / TTC

Operating Requirements

- Voltage Supply 400 V / 3 Phasen

- Average power required during warm-up 24 kW / 6.5 kW

- Exhaust Volume 2 × 10 m³ / min

- Nitrogen (optional) 5 bar

- Operating Environments 5 – 40 °C, 20 – 65 % RH

Standards (selection)

- Automatic chain oiling system, UPS, Board-Drop / Jam-Alarm, On-Off-Timer, 3 years of a JUKI warranty (incl. blower fans / heating elements)

Available options and accessories (selection)

- Dual lane configuration, automatic setting of conveyor width and CBS position