Fully Automatic Vision Screen Printer | JUKI G-Star

- Category: SMT Stencil Printers

- Manufacturer: juki

Handling M Size board, G-Star is adept at delivering all your business needs. It successfully attains 01005 miniature printing. Through full contact with the stencil, the improved cleaning system ensures that any remaining paste in the mesh will be eliminated before printing.

The 2D paste inspection function is able to detect insufficient paste, bridging and other defects. G-Star is also equipped with top and motorized side clamp, thereby ensuring superior printing quality.

- Product changeover time in less than 3 minutes

- Core cycle time (excluding printing and cleaning time) is less than 8.5 seconds

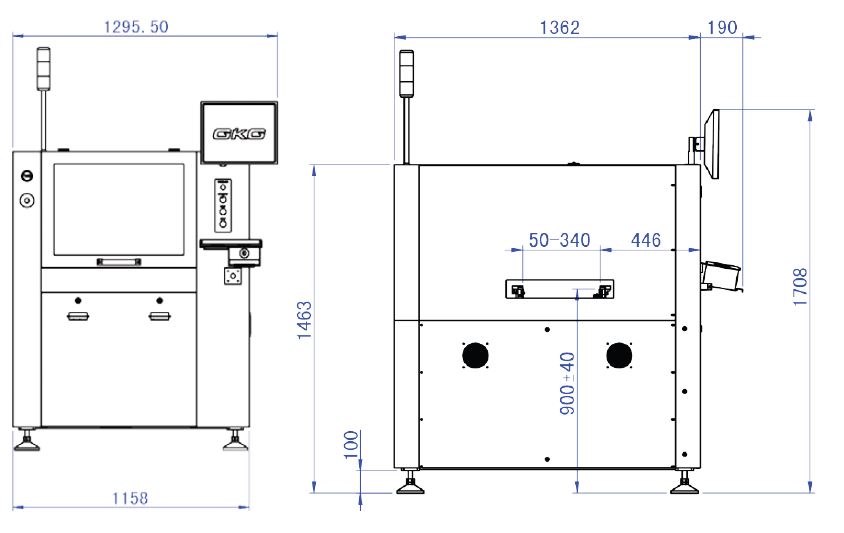

- Handles boards 50mm x 50mm min. to 400mm x 340mm max.

- New product set up time in less than 10 minutes

About the Fully Automatic Vision Screen Printer | JUKI G-Star

PERFORMANCE

- Machine Alignment Capability: 2Cmk @ ±12.5 microns 6 sigma

- Process Alignment Capability: 2Cpk @ ±25 microns 6 sigma

- Core Cycle Time (excluding printing & cleaning time): < 8.5 secs

- Product Changeover Time: < 3 mins

- New Product Set-up Time: < 10 mins

BOARD HANDLING

- Max. Size (L x W): 400 mm x 340 mm

- Min. Size (L x W): 50 mm x 50 mm

- Thickness 0.4~6 mm

- PCB Thickness Adjustment: Manual (Auto is option. PCB max. width reduced to 310 mm)

- PCB max. weight: 3 kg

- PCB edge clearance: 3 mm

- PCB Bottom Clearance: 15 mm (7 mm with optional auto PCB thickness adjustment)

- PCB Warpage: Max. 1% diagonally

- Clamping Method: Top clamp (manual) and motorized side clamp

- Support Method: Magnetic support pins, bars, blocks, Vacuum suction

- Conveyor Direction: L to R, R to L, R to R, L to L (software control)

- Conveyor Height: 900 ± 40 mm

- Conveyor Speed: (max.) 1,500 mm/s

- Conveyor Width Adjustment: Automatic