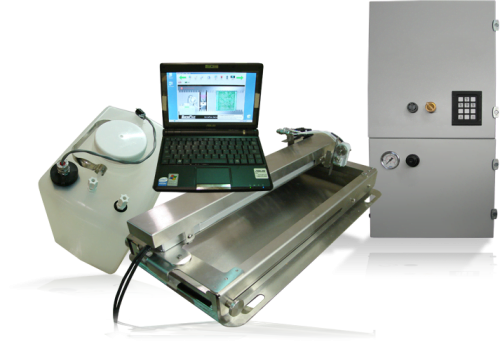

Fully Automated Reciprocating System With Selective Fluxing Capability

- Category: Fluxing Systems for Wave Solder Machines

- Manufacturer: Sonotek

A fully automated reciprocating ultrasonic wave solder spray fluxing system with selective area fluxing capability, available dual flux, and InSight auto board recognition functionality. Easy integration and operation with all wave solder machines and designed for medium to high mix lines. All SonoFlux systems feature non-clogging, repeatable, low maintenance ultrasonic spray performance with up to 80% reduction in flux consumption.

About the Fully Automated Reciprocating System With Selective Fluxing Capability

Complete flexibility - making it ideal for contract manufacturers making frequent product changeovers.

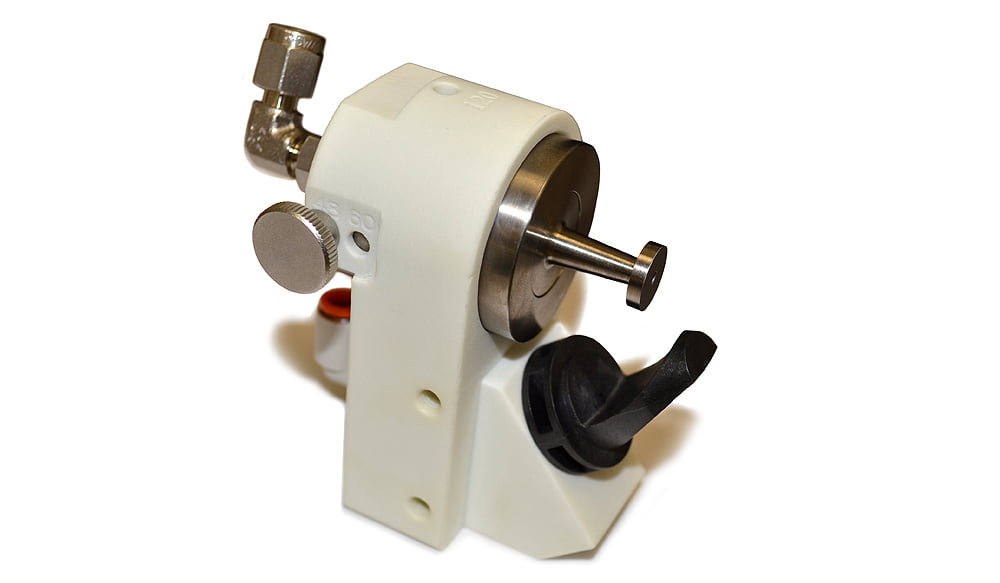

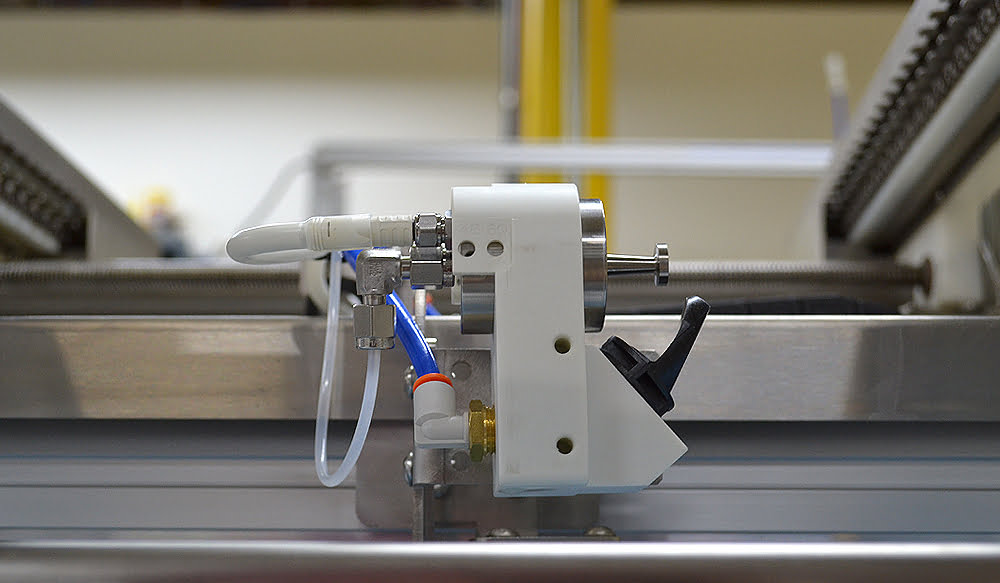

Designed for spraying water soluble/organic acid fluxes. All of the wetted materials, including the pumping system, liquid lines, fittings and ultrasonic spray nozzle are constructed with materials that are proven compatible with these very corrosive fluxes. The SonoFlux Servo WS incorporates Sono-Tek's non-clogging ultrasonic spray nozzle with our high Impact controlled velocity air shaping technology for excellent through hole penetration without overspray.

In addition, the SonoFlux Servo WS allows selective fluxing of pallets or full area coverage, with user-friendly programming and recipe storage controlled via a compact notebook using Windows®-based software. This versatile system is easily integrated with all major wave solder machines. The flexibility of selective area fluxing or full board width coverage combined with the ability to spray aggressive high solids fluxes without clogging makes the SonoFlux Servo WS an important tool for PCB manufacturers worldwide.

Optional InSight automated board recognition is available for fully automated recipe change. Boards are recognized using either an imaging camera or bar code scanner system. InSight ‘s intuitive software allows you to easily associate existing recipes with each board’s image or bar code. Once assigned, associated recipes can be automatically queued with the image recognition or bar code reader, without operator intervention.

Features:

- 500,000 recipe storage

- Single or dual mode fluxing

- Easy integration and operation with all wave solder machines

- Non-clogging ultrasonic atomizing nozzle

- High precision flux delivery pump

- Conveyor speed sensing option

- Low maintenance design reciprocator

- Uniform coverage

- Reduction in flux consumption up to 80%

- Programmable selective fluxing capability

- Dual flux option

Basic Specifications

| Reciprocator Dimensions: 46 cm (18”) configuration: 84 cm x 41 cm (33” x 16”) or 61 cm (24”) configuration: 104 cm x 41 cm (41” x 16”) |

| PCB Width Range: 50-457mm (2–18 inches) or 50-610mm (2-24 inches) |

| Control: PC-based |

| Flux delivery: High precision gear pump |

| Power Requirements: 110/120 VAC, 50/60 Hz or 220/240 VAC, 50/60 Hz, Single phase, 900 VA max |

| Air: 345-689 kPa (50-100 PSI) @ 170 LPM (6 CFM) |

| Motors: Closed loop drive with ball screw |

| Certification: CE |

| Ultrasonic Nozzle Designs: Impact flux head |

OPTIONS:

External enclosure and conveyor, auto dual flux, InSight board recognition system, conveyor speed sensing, bar code reader, aggressive flux configuration.