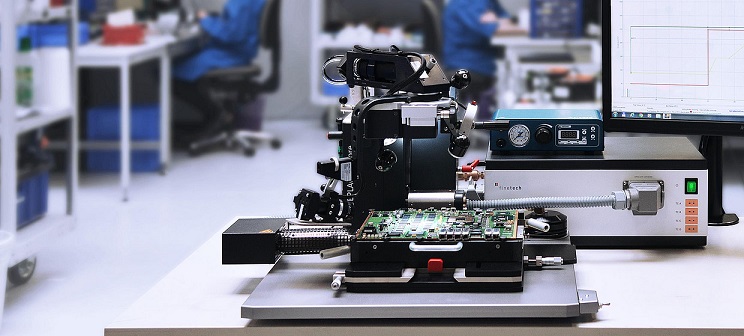

FINEPLACER®coreplus

- Category: PCB Rework Equipment

- Manufacturer: Finetech

Hot Air SMD Rework Station

The FINEPLACER® coreplus is a universal hot air rework station for electronic components and assemblies.

The complete rework cycle, including desoldering and soldering the component, residual solder removal and reballing, can be performed on the same compact rework system. The spectrum of compatible surface-mount devices ranges from very small (01005) to large components (BGA).

The full-area Bottom Heating Module has been optimized for reworking medium sized PCB of consumer electronics (tablets, laptops, gaming consoles) or medical technology products (i.e. MRT devices).

A pre-installed profile library and an intuitive visual user experience enables new operators to pick up work immediately. Numerous professional features, such as digital top heater calibration, precision touchdown force control and live process observation, make the FINEPLACER® coreplus a future-proof investment when the demands get tougher.

About the FINEPLACER®coreplus

Key Facts*

- Full hot air rework system

- Unique FINEPLACER® working principle

- Industry-leading thermal management

- In-situ process observation in HD

- Data/media logging and reporting function

- Full process access & easy visual programming with touch screen interface

- Sequence control with predefined parameters

- Placement accuracy better 10 µm

- Versatile machine platform

- Customer specific tooling

- Overlay vision alignment system (VAS) with fixed beam splitter

- 3-color LED illumination

- Full process access and easy programming

- Synchronized control of all process related parameters

- Software controlled top heater calibration

- Modular machine platform allows in-field retrofitting during entire service life

- Individual configurations with process modules

- Fully manual or semi-automatic machine versions

- Force controlled component handling