FINEPLACER® femto 2

- Category: R&D Bonders

- Manufacturer: Finetech

Advanced Automatic Sub-Micron Bonder

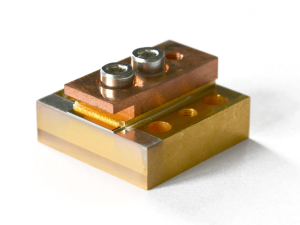

The FINEPLACER® femto 2 is a fully-automated die bonder with a placement accuracy of 0.3 µm @ 3 sigma that offers unrivaled flexibility for prototyping & production environments.

A complete machine enclosure allows very demanding applications in a controlled environment. Fully protected from external influences, this automatic flip chip bonder stands for highly stable assembly processes with the focus on maximum yield.

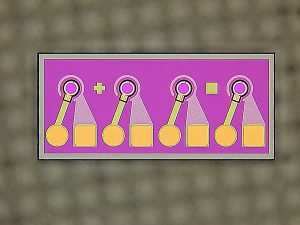

The new generation of the femto automated die bonding platform adds numerous innovations to the proven technical basis. This includes the cutting-edge FPXvisionTM. Combined with a refined pattern recognition, this all-new Vision Alignment System opens up a new dimension of application flexibility and accuracy. IPM Command, the fully revamped FINEPLACER® operating software, supports a consistent, ergonomic and clearly structured process development.

Depending on the requirements, the modular design of the automated die bonder FINEPLACER® femto 2 can be individually configured and retrofitted at any time to support new applications and technologies. This makes this automatic flip chip bonder a perfect tool and reliable companion as applications migrate from product development to production. This automated bonding system covers the entire workflow of inspection, characterization, packaging, final test and qualification in semiconductor, communications, medical and sensor technologies.

About the FINEPLACER® femto 2

"The FINEPLACER® femto 2 has enabled our company to realize higher throughput automation of our high accuracy flip chip bonding operations. As our high reliability opto-electronic transceiver business is expanding, this has helped us to satisfy our customer’s growing needs."

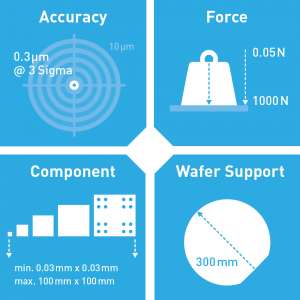

Key Facts*

- Placement accuracy of 0.3 µm @ 3 Sigma on small to large substrates

- Automatic placement accuracy calibration

- Wide range of controlled bonding forces

- UHD vision alignment system with FPXvisionTM

- Multi-chip capability

- Safe and controlled process environment with cleanroom quality

- Wide range of component presentation (wafer, waffle pack, gel-pak®)

- Modular machine platform allows in-field retrofitting during entire service life

- Large bonding area

- Numerous bonding technologies (adhesive, soldering, thermocompression, ultrasonic)

- Ultra low bonding force

- Individual configurations with process modules

- Various bonding technologies in one recipe

- Integrated scrubbing function

- Process module compatibility across Finetech platforms

- Wide range of supported component sizes

- Synchronized control of all process related parameters

- Process and material traceability via TCP (for MES)

- Full process access & easy visual programming with touch screen interface

- Data/media logging and reporting function

- 3-color LED illumination

- In-situ process observation in HD

- Fully automatic and manual operation

- Automatic tool management