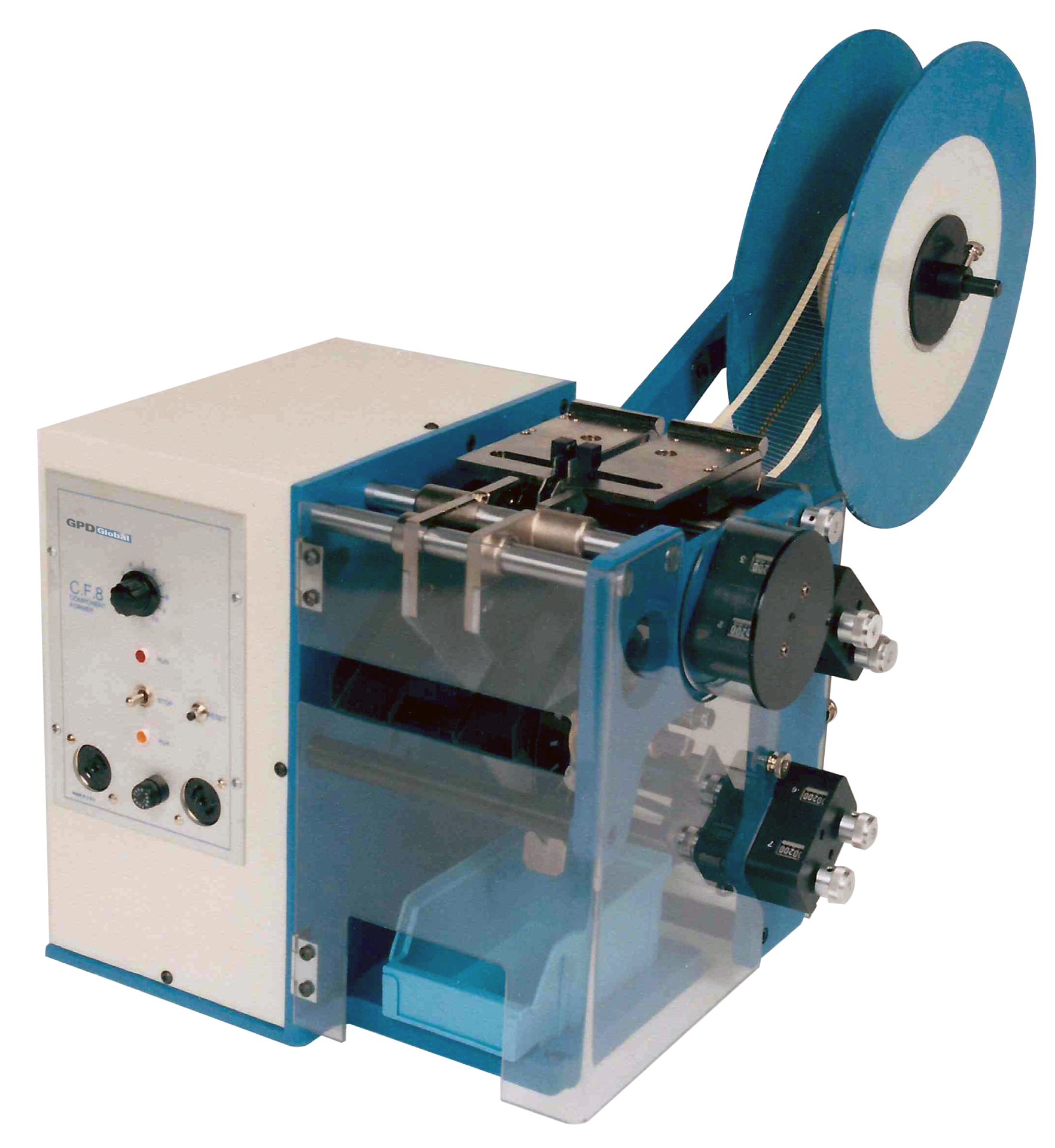

Precision Lead Former for Axial Components CF-8

- Category: Lead Formers

- Manufacturer: GPD Global

The Most Versatile Axial Component Lead Former In The World

The versatile GPD’s CF-8 lead former eliminates component body stress and meets exacting military standards for forming axial leaded components. Simple tooling changes make short or long run production jobs quick and easy.

About the Precision Lead Former for Axial Components CF-8

CAPABILITIES & FORMING FUNCTIONS

Its transport wheel system holds the component by the body as the component travels through the crimping and forming stations.

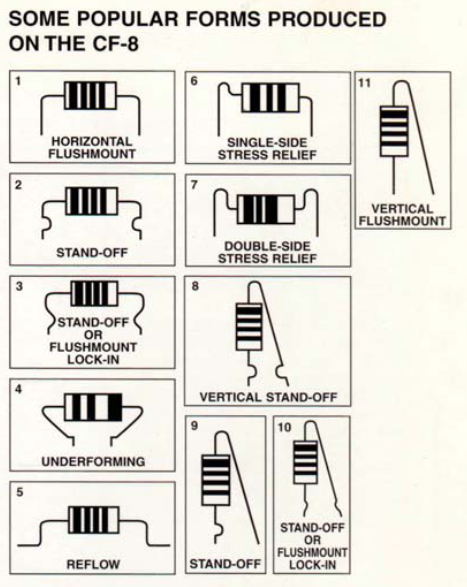

The CF-8 forming process eliminates component body stress by first crimping a lead on one side of the component body and then crimping the lead on the other side. After the leads are crimped, the component advances to the bending station where the leads are held and formed by a roller mechanism that produces nick-free results. The CF-8 is unique - it can form axial leaded components either vertically or horizontally with a simple die change. The extended stroke capability of the CF-8 allows ±.005” (±0,13 mm) control over lead length.

Versatility is the key word for the CF-8. Simple tooling changes make both short and long run production jobs quick and easy.

Repeatability of station settings are controlled to ±.002” (±0,05 mm) via positive pressure on the adjustment shafts. Components can be processed from either bulk or reel-and-tape feed systems. Numerous die sets enable you to reproduce many forms for horizontal or vertical positioning including: stress relief (single or double side), flushmount or stand-off lock-in, reflow, and underbody forming.

KEY FEATURES

- Control lead protrusion below the pc board with cut-off lock-in tooling to eliminate post solder trimming.

- Lock-in tooling prevents component "float" during wave solder process.

- Stand-off or flushmount lock-in forms for components with lead diameter from .015" to .060" (0.38 mm to 1.52 mm) and lead material from copper to steel.

- Feed loose or taped components with the same machine. Feed from reels with standard Tape Feeder or in bulk with optional Jacobs Ladder.

- Reduce setup time through repeatable station settings and GPD's exclusive Calculator Software Package.

- The CF-8 meets the most difficult standards for stress-free/nick-free forming during the forming sequence.

- Standard tooling in stock.

- Station adjustments available in inches or metric.

Capabilities

- Meets exacting military standards

- Extremely low maintenance

- Eliminates component body-to-lead stress

- Forms axial leaded components either vertically or horizontally

- Repeatability of station settings are controlled to ± .002" (0.05 mm)

- Form loose or taped axial-leaded components

- Tooling change-over is quick and easy

- Form components with lead diameters between 0.015" (0.38 mm) and 0.060" (1.52 mm)

PRODUCTION RATES

- Tape mounted components up to 25,000 parts per hour

- Loose fed components up to 4,000 parts per hour

ACCESSORIES

A complete line of accessories ranging from the Calculator Software to an Electronic Counter to the Transport Wheel System is available for use with the CF-8.