Automatic PCB Stencil and Screen Inspection System – ScanSTENCIL™

- Category: SMT Stencil Inspection

- Manufacturer: ScanCAD

A fully integrated, stand-alone measurement and inspection workstation for use after stencil and screen fabrication or other machined, etched, e-form or laser cut operations. For stencil and screen users, the system permits in-bound and post cleaning inspection of stencils and screens prior to production.

- Compare Parts against Gerber or Golden Part

- Verify feature absence/presence as small as 0.001″ (0.025mm)

- Check Gerber Image against Scanned Image

- Compare Gerber Image against Gerber Image

- Design Rule Check

- 15+ inspection algorithms

- Masking capability

- Ability to overlay 90+ images & 90+ CAD layers

About the Automatic PCB Stencil and Screen Inspection System – ScanSTENCIL™

Why use ScanSTENCIL?

- Quality - 100% automatic inspection of screen/stencils for absence/presence, position and size of apertures.

- Accuracy - NIST traceable calibrated system. Check apertures as small as 0.001” diameter (0.025 mm).

- Usability - Adjust Stencil Gerber data to match actual PCB to achieve 43% reduction in Solder Paste defects per published Motorola study in SMT007 Magazine.

- Flexibility - Use one system for inspection and measurement of stencils/screens, bare PCBs, pallets, tooling, components, etc.

- Traceability - Store images and inspection data for traceability in support of ISO and other compliance programs.

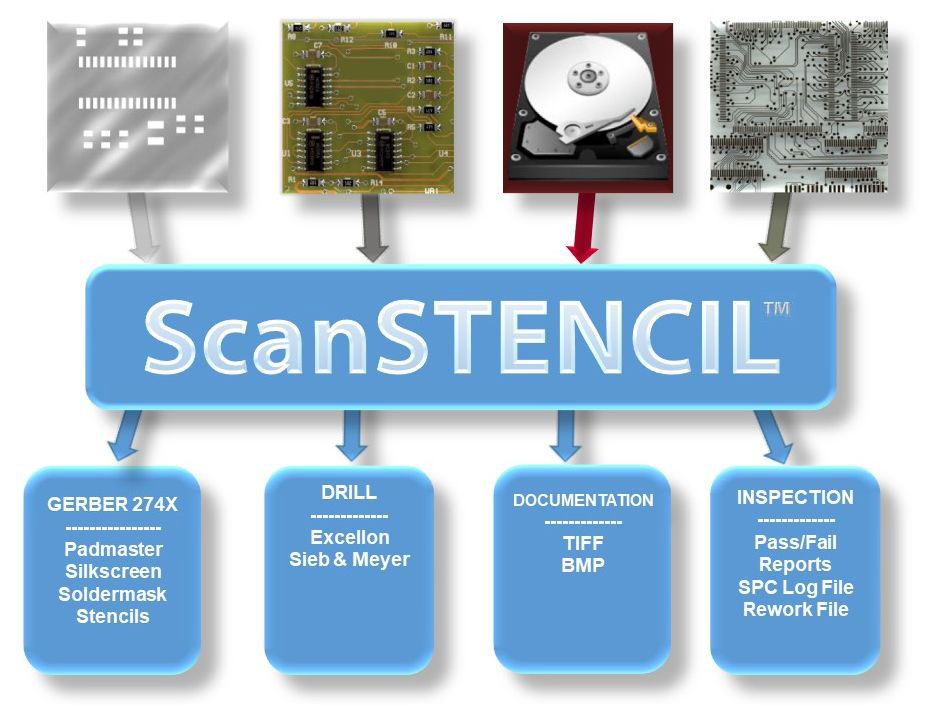

ScanSTENCIL uses a PC Windows-based software package integrated with a high-resolution, calibrated, A3 size flatbed scanner. This combination allows inspection of both stencils and screens for accuracy and the ability to inspect 100% for absence/presence, position and size of thousands to millions of apertures.

Create Stencil Fabrication Data

ScanSTENCIL adds flexibility to the stencil and screen inspection process. Utilizing its calibrated scanner, ScanSTENCIL inputs actual PCBs, existing stencils, screens, films and technical drawings. With these inputs, ScanSTENCIL is able to automatically create exact Gerber data for stencil/screen production when data is corrupt or missing. Also able to modify Gerber data to exactly match a PCB, thereby creating a "Digital Twin".

Automatic Features

Tired of using slow manual measurement and inspection methods? ScanSTENCIL offers various functions that quickly and automatically create necessary Gerber and verification data:

- Absence/Presence of Apertures

- Confirm Proper Aperture Position

- Confirm Proper Aperture Shape and Size

- Compare Stencil/Screen vs. Gerber

- Compare Stencil/Screen vs. Stencil/Screen

- Compare Stencil/Screen vs. PCB

- Create Stencil Files from Boards/Films

- Automated features to speed inspection process

Verification

Worried about the quality of new or used and just cleaned stencils or screens? Use ScanSTENCIL to verify the accuracy of the parts and (Gerber) data. The "Local Micro Alignment" (LMA) option allows for checking apertures as small as 0.001” diameter (0.025 mm).

Additional Applications

ScanSTENCIL creates Gerber files as well as other data used in stencil production, including: Silkscreens, Soldermasks, Padmasters, Stencil Files, Panelized Images, DXF and Gerber-274x files, etc. ScanSTENCIL permits fast and accurate comparison of stencils/screens to bare PCBs bringing automation and increased productivity to QC departments.

Using ScanSTENCIL's hardware “focus” capability, inspect printed and dispensed materials such as solder paste, glue and adhesive permitting first article and sampling inspection back to Gerber data.