AI-Based Solution for Inspection – TTC Fix

- Category: PCBA Traceability

- Manufacturer: Cogiscan

Powerful AI-based solution for fast & simple optical inspection with defect & repair management. TTC Fix catches 85% of common errors pre-reflow.

About the AI-Based Solution for Inspection – TTC Fix

YOUR CHALLENGE

Managing defects after soldering simply isn't efficient for your manufacturing operation – gobbling up precious employee resources, putting the PCBA at risk of damage, and eating into your already slim margins – you need a better way to catch, repair, trace, and manage both THT and SMT defects.

SOLUTION

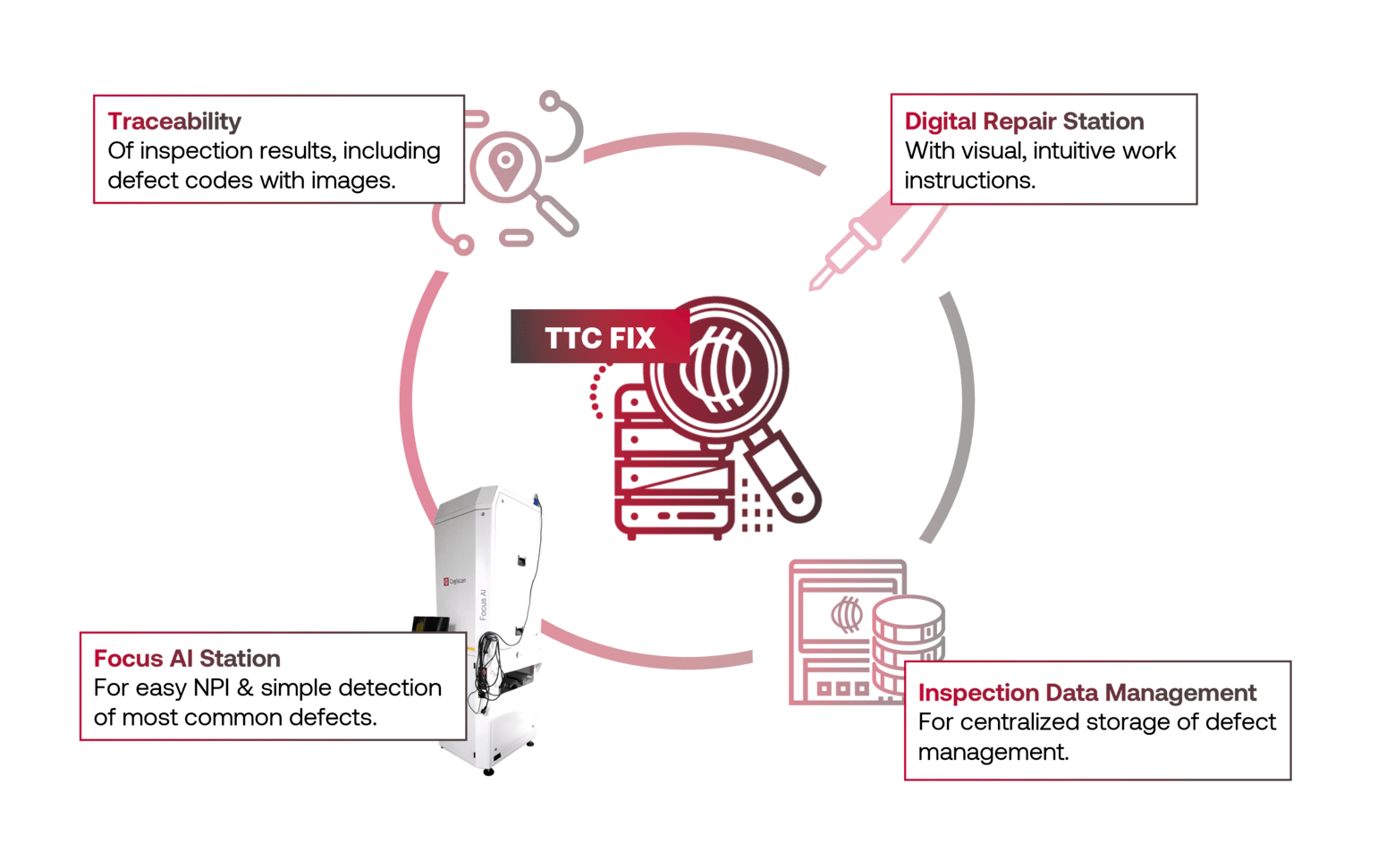

Our TTC Fix platform offers a robust and powerful solution for complete pre-solder defect management. Centered on the Focus AI station, a 2D inspection machine powered by an AI and machine-learning platform, its neural network quickly detects the most common errors for THT and SMT. Further enhanced by Cogiscan’s TTC Server software, TTC Fix includes an intuitive, visual repair tool as well as full traceability reporting of all defects including image files.

Features

- Digital Repair Station with visual and intuitive instructions.

- A visual representation of the board using standard like CAD or Gerber with highlighted defects.

- Failure image with complete defect information.

- Defect list with color-coded status.

- Zoom, search and filter functions.

- Inspection Data Management. TTC Fix uses Cogiscan's TTC Server software to centralize defect data and store them in a single place. You can also easily share inspection results data with other enterprise systems, such as your MES or ERP.

- Traceability - full traceability of inspection results, including defect codes and images. This feature enables compliance by maintaining a complete history of all inspections, defects & repairs.

- Focus AI Station - a 2D inspection station used prior to soldering (THT & SMT) to make sure you find and fix error before they become real defects soldered onto the product.

- AI Algorithms - TTC Fix is powered by an AI & machine-learning platform and uses a neural network to quickly detect the most common errors for THT and SMT.

Benefits

- Fast & Easy NPI: No engineering skills required to program new products – intelligent & automatic programming in less than 5 mins.

- Pre-Solder Detection & Correction: Find and fix errors early, before they become real defects for both THT and SMT components.

- Streamline Repair Process: Simplify and centralize digital repair & rework with user-friendly visual work instructions.

- Full Traceability: Enable compliance with a complete history of all inspections, defects & repairs.

- Low-Cost Inspection Option: Affordable alternative to manual inspection. TTC Fix comes at a cheaper price than a standard AOI, and comes with the added cost reduction of fixing errors before soldering.

What to expect?

Catches 85% of common errors including: missing components, upside-down components, misplaced components, skewed components, wrong polarity.

Reworks down by 51% after a 9-month implementation. Notes: From 11000 PPM to 5400 PPM after a 9-month project.