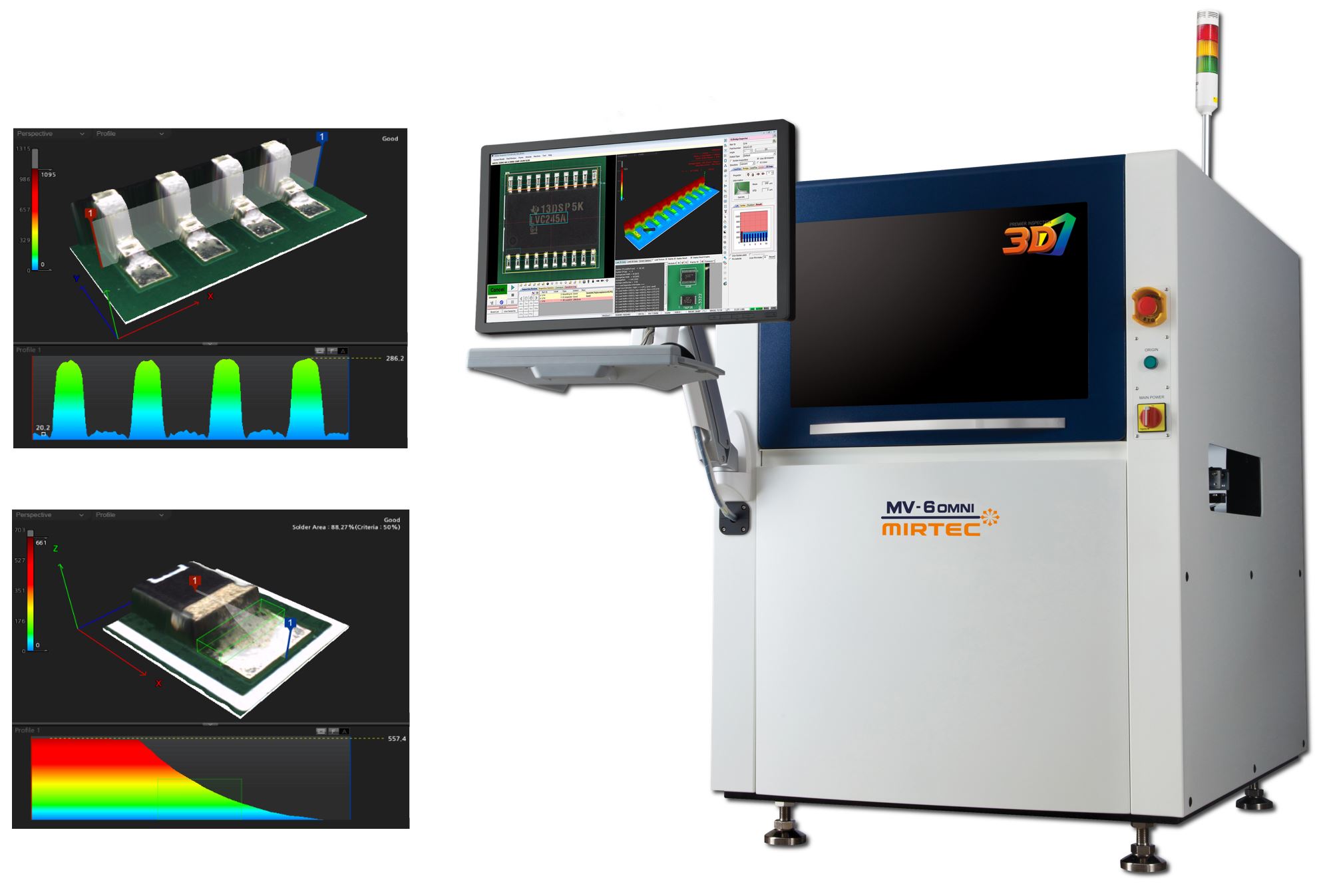

3D AOI SYSTEM : MV-6 OMNI

- Category: AOI Equipment

- Manufacturer: Mirtec

High-Speed / High-Performance 3D AOI SYSTEM

- FIFTEEN MEGA PIXEL CoaXPress Camera Technology

- Advanced Eight Phase Color Lighting System

- 10 Micron / Pixel Precision Telecentric Compound Lens Design

- Integrated Ten Mega Pixel SIDE-VIEWER® Camera System

- Precision Closed Loop AC Servo Drive Motor System

- Extremely Simple Programming and Operation

About the 3D AOI SYSTEM : MV-6 OMNI

The MV-6 combines 15 mega pixel CoaXPress camera technology with a precision telecentric compound lense system to provide 10 µm pixel resolution. When combined these technologies can detect the presence or absence of 01005 components. Projectors pointing in four directions record overlapping 3D shaded Moire lines and combine with an eight phase color lighting system to determine height of surface features, shapes of component bodies, slope acceptability of solder joints.

- Repeatability > +/- 10micron X/Y system

- Main camera is a 15Mega Pixel Camera with 10 micron resolution with a Telecentric Lens to give better perspective pictures.

- 4 Side Viewer cameras 10 Mega Pixels each

- PCB Size 50mmX50mm-460mmX480mm

- Minimum Component size 01005/.3mm Pitch

- 2D and 3D technology with height checking capabilities of +/- 5microns along with Co-Planarity inspection, solder llet 3D inspection, and Lifted component recognition.

- 8-Phase Color Lighting System

- Offline Programming software (OLTT) to keep machine uptime to an absolute maximum.

- Remote Repair system allows for any defects caught at the AOI to be repaired without taking any of the machines time allowing for more uptime on productive inspection.