Ultrasonic Spray Coating Robot

- Categories: Ultrasonic Spray Coating of Photoresist for MEMS Wafers, Photoresist & Polyimide Films Coating Systems for Photolithography, Protective Coatings for Package Level EMI Shielding, Ultrasonic Coating Systems for Protective Films for Dicing, Ultrasonic Spray Systems for Flip Chip Fluxing

- Manufacturer: Sonotek

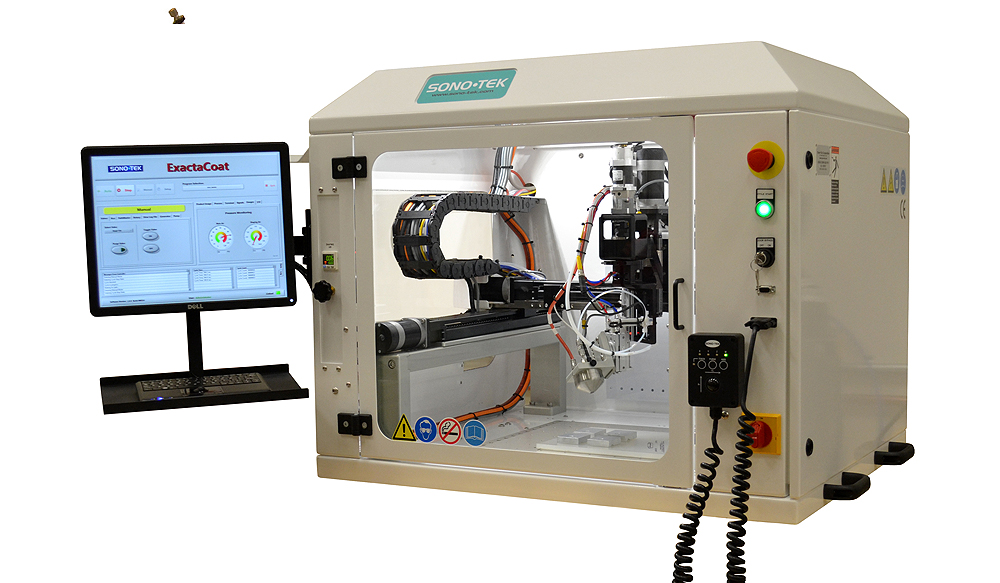

ExactaCoat Ultrasonic Spray Coating Robot – A Three-Axis Robot For Any Spray Coating Application

This system employs robust ball-screw slides driven by stepping motors. Any Sono-Tek ultrasonic nozzle can be integrated. Spray pattern widths can be easily shaped depending on which nozzle is used. An optional top frame is available to fully enclose the work area if required.

About the Ultrasonic Spray Coating Robot

Automated, programmable benchtop ultrasonic spray coating robot system with coordinated XYZ motion control using Windows-based software and user-friendly teach pendant with trackball. Versatile R&D to mid-volume production thin film coatings.

ULTRASONIC SPRAY COATING ROBOT INTEGRATED FEATURES:

- Compact benchtop design that favors portability

- 400 mm x 400 mm x 100 mm (15.75” x 15.75” x 3.94”) range of motion

- Includes Windows® based (programming) software

- Coordinated motion in all three axes simultaneously

- Base mount of the x-axis permitting motion of the work area

- Front panel LCD screen with function keys

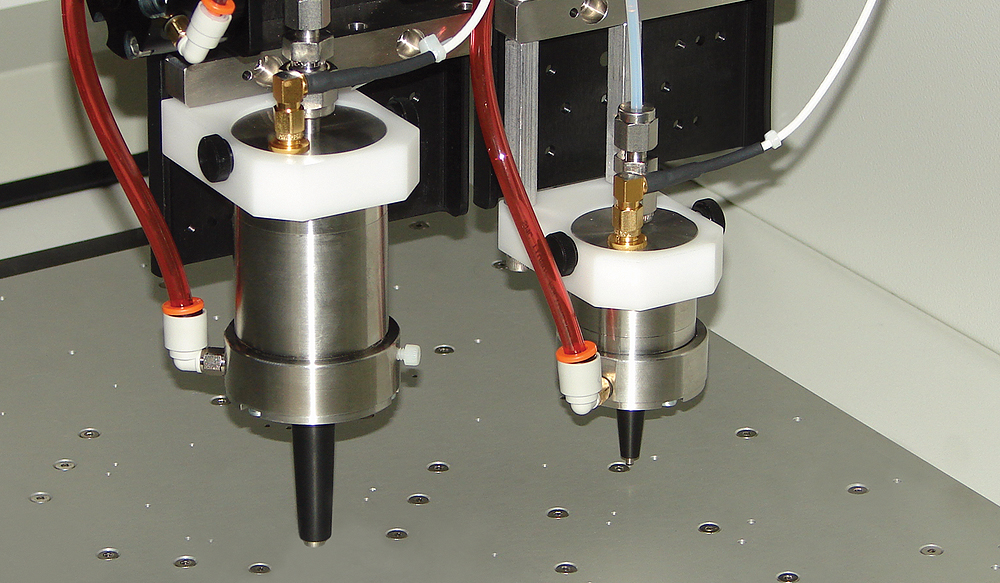

- Nozzles can be easily interchanged to produce spray patterns ranging from 0.010" to 6" wide

ULTRASONIC SPRAY COATING ROBOT NOZZLES FEATURES:

- Up to 80% reduction in material consumption

- Reduced wasteful overspray and atmospheric contamination

- Minimal servicing and downtime

- Spray patterns that are easily shaped for precise coating applications

- Highly controllable spray produces reliable, consistent results

- Non-clogging

- No moving parts to wear out

- Corrosion-resistant titanium and stainless steel construction

- Ultra-low flow rate capabilities, intermittent or continuous

ULTRASONIC SPRAY COATING ROBOT BASIC SPECIFICATIONS:

| Dimensions: 944 mm W x 831 mm H x 794 mm D (37.2” W x 31.2” H x 32.7” D) |

| Work Area*: 400 x 400 x 100mm (15.75” x 15.75” x 3.94”) *Note: Work area may be reduced depending upon system configuration |

| Control: Windows-based (PC included) |

| Power Requirements: 120V, 220V, +/-10%, 50-60Hz |

| Air: 551.6 kPa (80 PSI) dry unlubricated air |

| Motors: Brushless DC servo |

| Certification: CE |

| Ultrasonic Nozzle Designs: AccuMist, Impact, Vortex, MicroMist, or Propel |

OPTIONS:

| Heat and/or Vacuum Plate: 150, 250C heat/vac or 500C heat |

| Head configuration: up to two heads (Ultrasonic or Vector) |

| Common Options: Wire/rod coater, Ultrastatic ESC, Nozzle rotate and or tilt, 1 or 2 drawer load system, N2 Rich Environment, LEL Sensors, cleanroom upgrade, aggressive material upgrade |

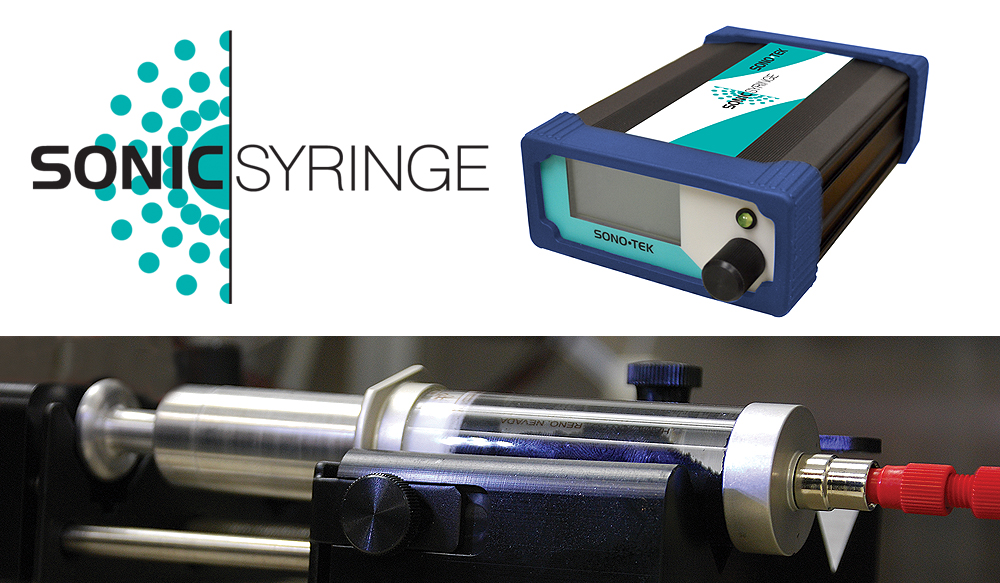

| Liquid Delivery: Common Liquid Delivery: Syringe pump (standard, Sonic or stirring), gantry mounted syringe pump, MicroFlow, SonoFlow Fusion, HyperFlow catalyst pump |

| *Additional custom options may be available depending upon application requirements |