SMT Pick and Place Machine

- Category: Pick & Place Equipment

- Manufacturer: juki

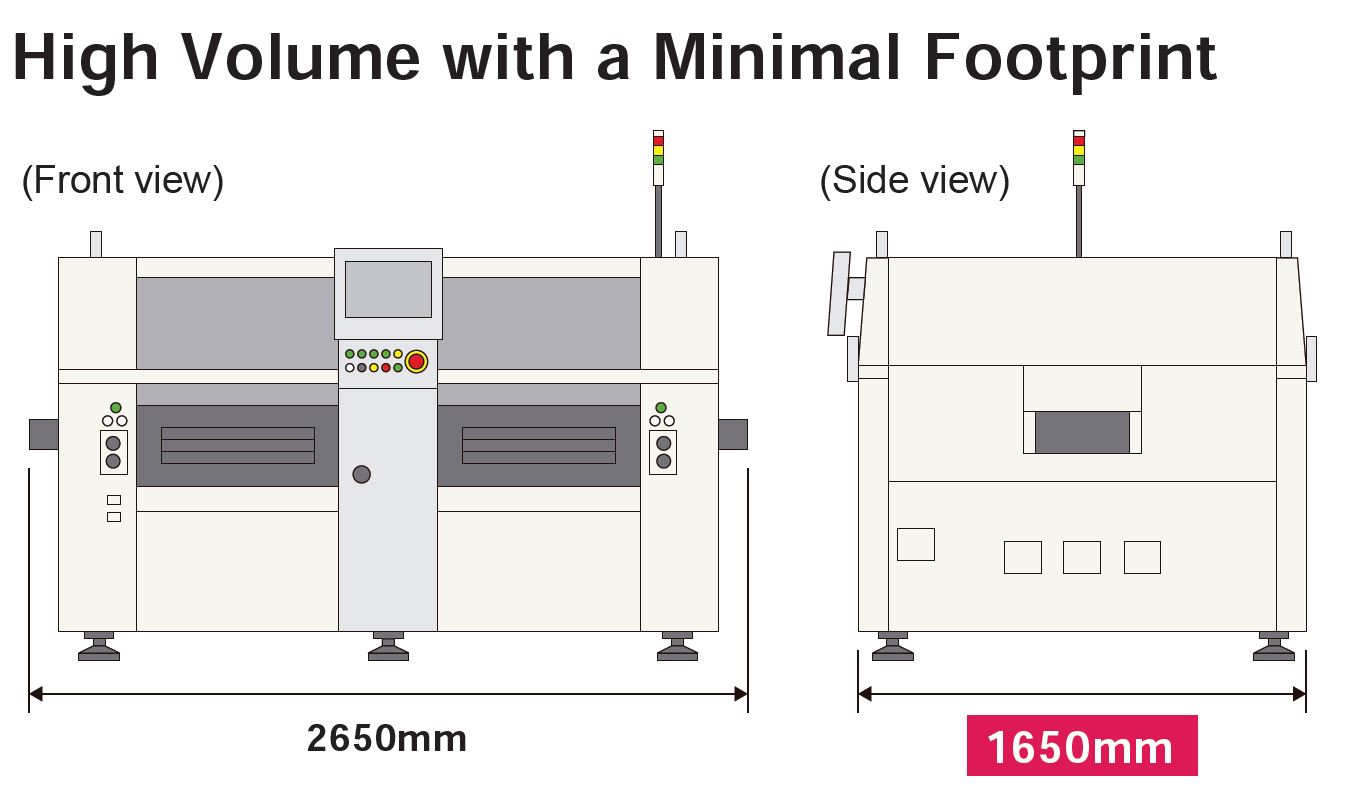

SMT Pick and Place Machine – Refined High-Speed, High-Precision Modular SMT Pick & Place

- 66,000 CPH (IPC9850)

- Electronic & Mechanical Tape Feeders

- 22” x 32” Maximum Board Size

About the SMT Pick and Place Machine

- Board Size:

- L Size: 410x360mm

- L-Wide Size: 510x360mm

- XL Size: 610×560mm

- Component Specs:

- Component Height: 6mm

- Component Size: Laser Recognition: 0402mm(01005 inch)~□33.5mm

- Feeder Inputs: Max.240 in case of 8mm tape (on a Electric double tape feeder)

- Placement Specs

- Placement Speed (chip):

- 0.040Sec./chip(90,000CPH)

- IPC9850: 66,000CPH

- Placement Accuracy: Laser Recognition: ±0.05mm(±3σ)

- Placement Speed (chip):

Developed under JUKI's "3E EVOLUTION" concept, the ever evolving FX series SMT pick and place machine has been redesigned for ease of use, efficiency, cost effectiveness and increased expandability and compatibility. Using new, highly efficient linear servomotors, lightening and stiffening the head unit, and reviewing the placement sequence allow for an effective tact of 0.040 s/chip (90,000 CPH) (optimum conditions).

From the pioneer of the modular assembly line comes the latest technology in high volume production at the lowest cost of ownership. Offering an interchangeable electronic and mechanical feeder solution combined with a new 22” x 32” maximum board size, the continuously evolving FX-3RA offers the utmost in flexibility, reliability, and ease of use for both high speed and high mix manufacturing environments.

- Four Gantry; 1 Head Per Gantry - Two Stations - 4Beams - 4Head Configuration

- 6 Nozzles per Gantry - A total of 24 nozzles

- High Accuracy Laser Align Component Centering - On-the-fly Simultaneous Centering using 6-nozzle Multi-laser Head

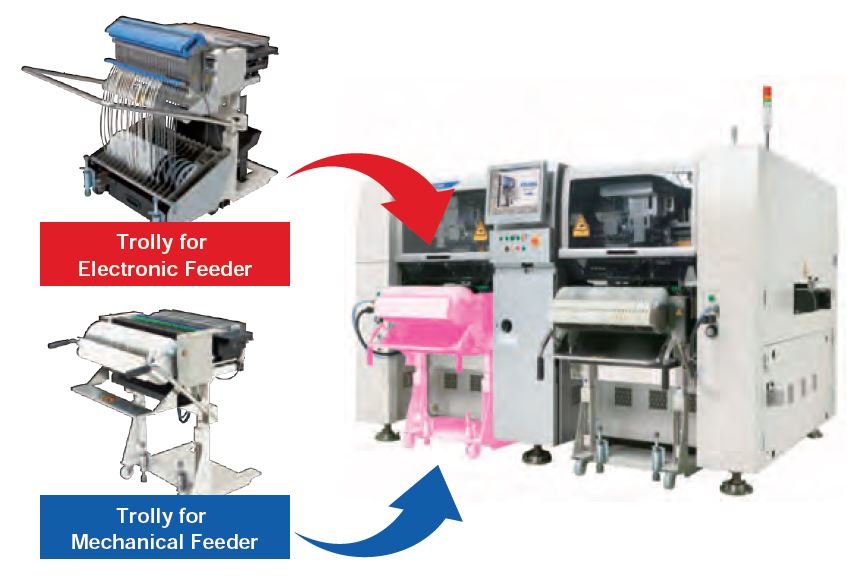

- Quick Change Feeder Trolleys - Compatible with mechanical and electronic feeders.

- X-Y Linear Servomotors - New linear servomotors and full closed-loop control

- Electronic Feeder Compatible - Using electronic double tape feeders enables mounting a max of 240 component types.

SMT Pick and Place Machine's Chip placement speed is greatly improved

Simultaneous picking and on-the-fly parallel recognition with six nozzles are achieved by using the high resolution LNC60 laser sensor.

A SMT Pick and Place Machine with Unrivaled placement range from 01005 (0402 metric) to 33.5mm square components

The LNC60 brings a new concept in laser centering to the market. This sensor has the unique ability to center components from 01005 (0402 metric) to 33.5mm square parts. From ultra-small, ultra-thin, chip-shaped parts to small QFP, CSP, BGA, a wide range of parts can be mounted by the laser recognition system at high-speed and with high-accuracy.

This SMT Pick and Place Machine Supports a Wide Range of Components

FX-3RA can widely recognize and place angular parts ranging from 01005 (0402 metric) to 33.5mm square. By combining it with a High-speed Flexible Placement System KE2080 or KE3020V, placement parts are effectively sorted supporting highly flexible production capability.