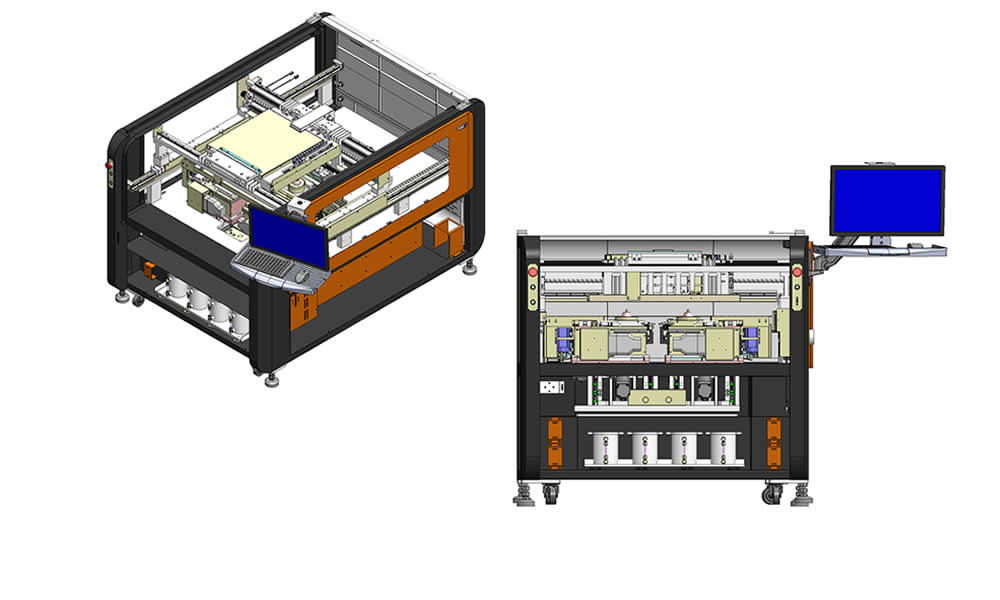

Selective Wave Soldering Machine – Unit-i4

- Category: Compact Inline Selective Soldering Machines

- Manufacturer: SASinno

A New Generation Of Selective Wave Soldering

Highest output, highest ROI, highest flexibility, compact inline system. Unit-i4 combines a drop jet fluxer nozzle, bottom IR preheating, selective solder pot and AOI Function. The result is a full-function station for fluxing, preheating, soldering, and inspection.

About the Selective Wave Soldering Machine – Unit-i4

- 2 drop jet fluxers

- Bottom IR preheating

- 2 solder pots in two individual wave tunnels, each with two wave tunnels

- The PCB is moved by a conveyor, the conveyor table moves in X/Y, the solder pot/fluxer movies in Z

- Windows 10 system

- 3-axis full servo drive with ball screw movement

- Standard equipped with wave height calibration

- Real-time soldering process monitor

Specifications

| Item | Unit-i4 |

| General | |

|---|---|

| Operating power/Max power | 6KW/22KW |

| Machine dimension | 1300(L)*1840(W)*1200(H) |

| Net weight | 700KG |

| Power supply | 3PH 380V 50HZ |

| Air supply | 3-5 bars |

| Exhausting required | 800M3/h |

| PC | Yes |

| Typical Program Time | 10 Minutes |

| Conveyor | |

| PCB dimension | W50xL50---W508xL508mm(single nozzle soldering) W50xL50---W508xL250mm(two nozzle soldering parally) W50xL50---W250xL250mm(four nozzles soldering parally) |

| PCB Clearance | Top 95mm bottom 30mm |

| PCB Weight | Max 5kg |

| Conveyor width | Auto |

| Conveyor assembling motion | X,Y motion with server motor/driver |

| PCB Robotic Platform | |

| Flux Nozzle Type | Drop jet fluxer |

| Flux Nozzle Quantity | 2 |

| Flux Tank Capacity | 1L |

| Flux Tank Quantity | 2 |

| Flux Nozzle Distance | adjustable |

| Preheat | |

| Preheating method | Bottom IR heater |

| Solder Management | |

| Solder pot type | mechanical pump |

| Standard Solder Stations | 2 |

| Solder Pot Capacity | 30 kgs |

| Solder Temperature Control | PID |

| Heat-UpTime | About 30mins |

| Max Temperature | 350°C |

| Wave tunnel | 4pcs (2pcs per solder pot) |

| Mini Wave Nozzles | Dia 3to12mm |

| Customized nozzle | Available |

| Axes of Motion | Z1, Z2 |

| (N2) Inertion Management | |

| N2 Consumption per Nozzle | 6--8m3/H |

| Required N2 Purity | >99.99% |