All-In-One Selective Soldering System | JUKI iCube

- Category: Selective Soldering Equipment

- Manufacturer: juki

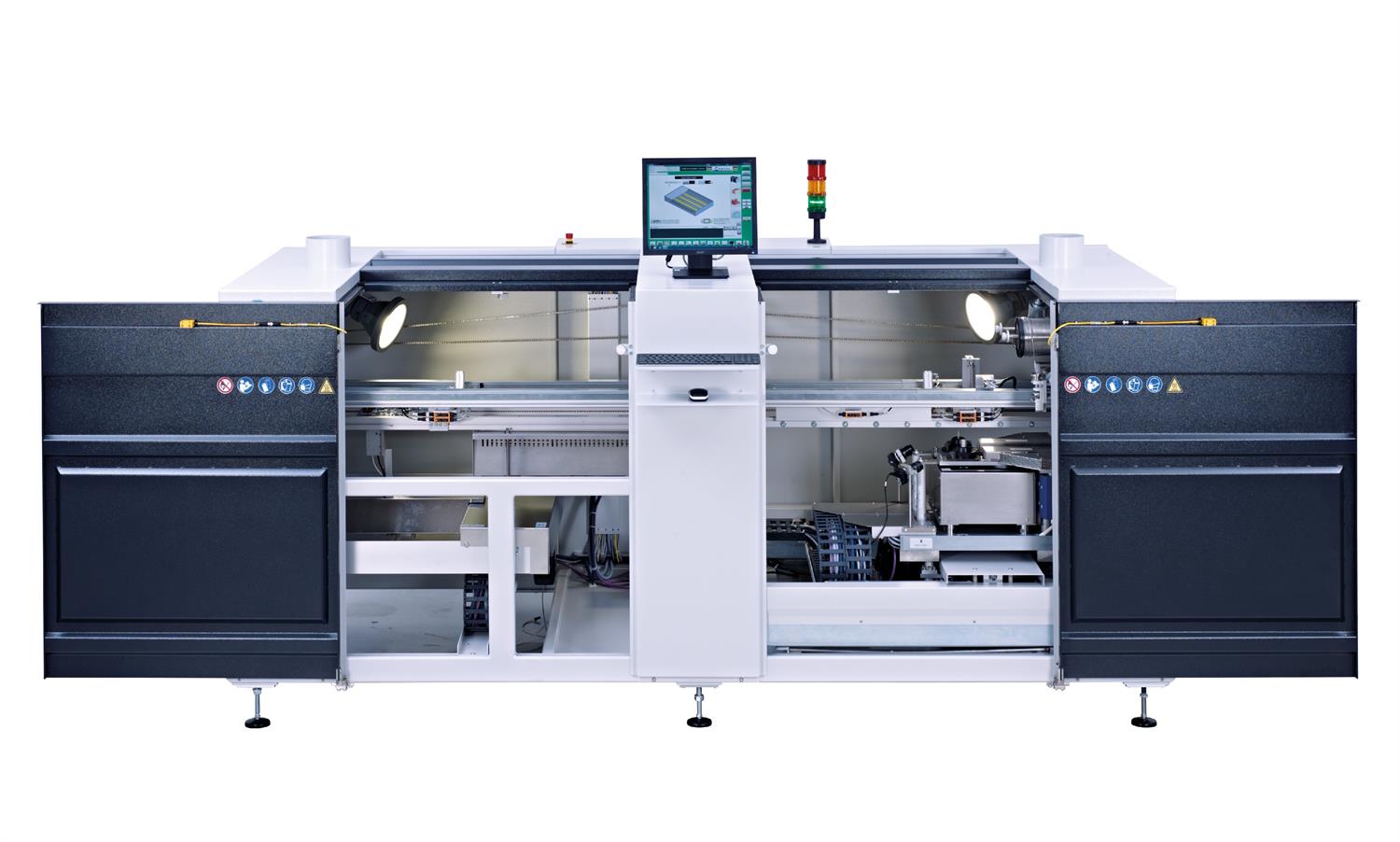

All-in-One Inline Selective Soldering Machine

High quality, flexibility and reliability offered in a complete all-in-one package is what you get with the inline iCube Selective Soldering System. Feature rich and designed for high-end production, the iCube is the answer to all of your soldering needs.

About the All-In-One Selective Soldering System | JUKI iCube

STANDARD FEATURES:

- Closed loop servo axis for solder pot and fluxing unit

- 25 to 30 Kg Pb free ready solder pot (depends on alloy)

- Heated N2 at the soldering nozzle

- Bottom side fast reacting quartz preheater

- Automatic wave RPM adjustment

- Live process viewing camera

- Micro-dot drop-jet fluxer

- SMEMA conveyor system with top clamping

- Offline programming for Gerber or JPG

ADVANTAGES:

- All-in-one selective soldering system

- Processes 3 PCBs simultaneously: (1) PCB in the fluxer, (1) PCB in the preheat station, and (1) PCB in the soldering station ensuring faster cycle times.

- Many selective soldering machines have only an “optional” topside preheater available. Preheating is a critical stage of the process in selective soldering, especially with Pb free alloys and thermally challenging PCB’s. For this reason the iCube comes standard with a full size IR bottom side preheater and optional dual topside IR or convection preheaters that will ensure proper flux activation and perfect topside fill even on the most challenging products. An optional closed loop pyrometer can ensure the required temperatures are reached before releasing the PCB to the soldering process, and also maintain the heat on the PCB during the soldering process.

- Offline programming software is included and can be used either with Gerber or JPG’s. There is no need to interrupt production to make new programs.

- Accessibility to the entire machine for easy maintenance has been something JUKI has maintained throughout the evolution of our Selective Soldering Products. This has not changed on the iCube.

OPTIONS:

- Dual nozzles in separate solder pots for same or dual alloys

- Additional solder pots for different alloys

- Specialty solder nozzles

- Topside preheater (over bottom side preheater)

- Topside maintenance heater (over process area)

- Automatic fiducial correction

- Board warpage control

- Closed loop pyrometer control on the preheaters

SPECIFICATIONS:

- Dimensions: L3000mm W1550mm H1310mm (119" x 61" x 52")

- Board Size: Min. 80mm x 50mm (3.1" x 2"), Max. 510mm x 460mm (20" x 18")

- Flux Head: Micro-Dot Drop-Jet

- Preheat:

- Bottom: Quartz IR emitters

- Top (Optional): Quartz IR to Convection

- Topside Maintenance Heat: Quartz IR to Convection