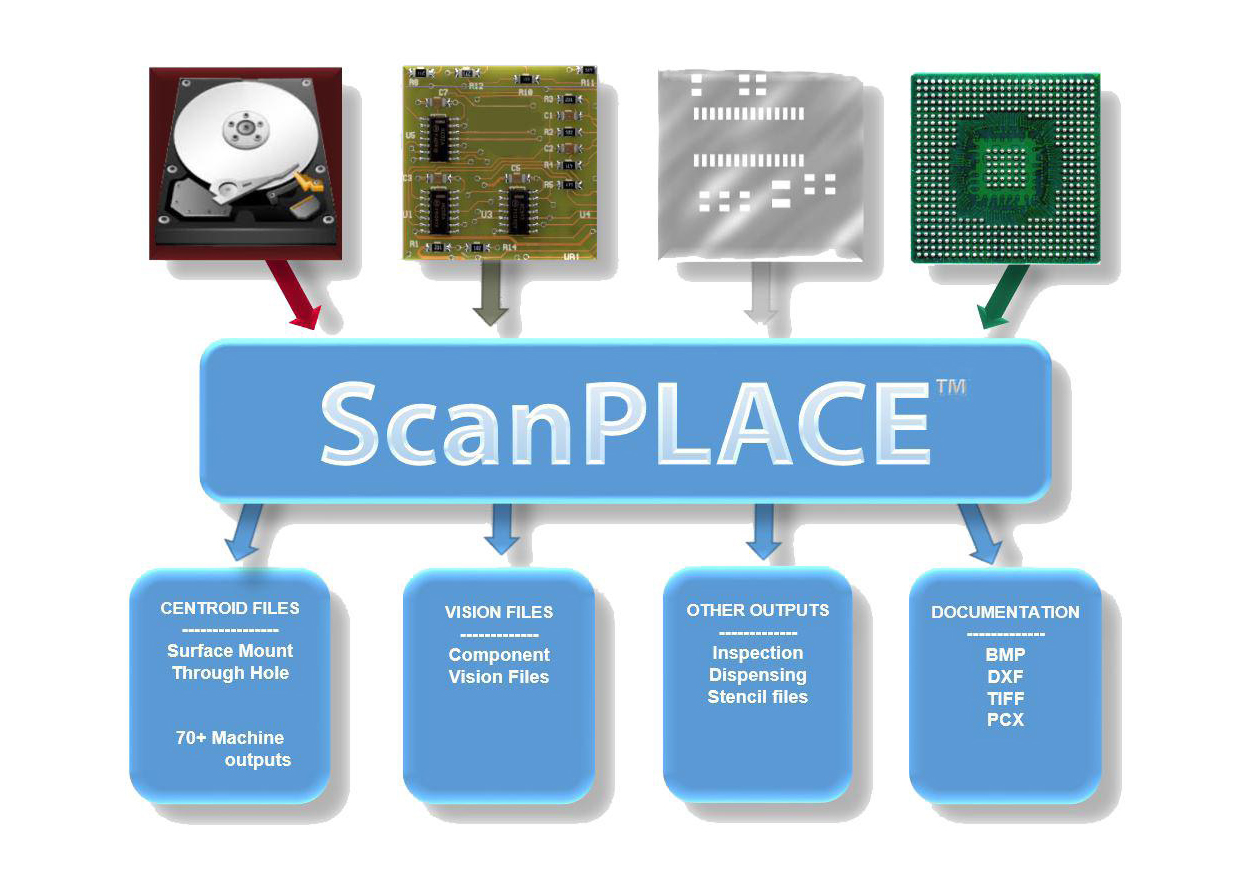

PCB Assembly Machine Offline Programing, Measurement & Inspection Software – ScanPLACE™

- Category: PCB Reverse Engineering, Redesign, & Repair Software

- Manufacturer: ScanCAD

A fully integrated, off-line programming, inspection and measurement workstation.

A sophisticated and user-friendly alternative to complex CAM software packages and inaccurate and time-consuming manual inspection and programming methods that cost assembly houses productivity, time and money.

About the PCB Assembly Machine Offline Programing, Measurement & Inspection Software – ScanPLACE™

Why use ScanPLACE?

- FLEXIBLE - Use one workstation to produce assembly files for multi-vendor Surface Mount, Insertion, Test, Inspection and Dispensing machines.

- POWERFUL - Use one workstation to inspect stencils, screens and bare or loaded boards.

- FAST - Decrease programming time from days to hours.

- EASY - Windows-based system

Programming

Using a calibrated, high-resolution, color imaging system, ScanPLACE produces assembly programs and process documentation for Surface Mount, Insertion, Test, Inspection and Dispensing machines.

Import / Scan

- CAD, Components, Boards, Film, Stencils, BOM and Gerber Data.

Output

- Component Pitch, Rotation and body dimensions

- X/Y Component Centroid

- Reference Designator & Package ID

- Part, Feeder/Magazine Number

- User Defined Data

- Gerber Data

- Process Documentation

- Multiple machine specific CAD files (IMC, SMT, TEST, AOI) and Stencil file generation during one programming session

- Component Information for Vision Databases

In-bound Board & Stencil Inspection

ScanPLACE increases production efficiency by using off-line comparison of actual PCBs and Stencils against Gerber files and/or a "golden board." Pre-production check verifies revisions against each other before the first production run. Eliminate surprises.

Build Component Libraries

Scan a component to automatically calculate and register the following information:

- Lead Pitch, Lead Size, Body Size

- Lead Groups, Pick Up Location, etc.

- Specific Vision Data outputs for Fuji SMD3 and Siemens SIPLACE

- Generic Vision ASCII files for other suppliers

Offline Inspection & Measurement

ScanPLACE uses a combination of editing functions to ensure that all information has been inserted correctly. This off-line verification significantly reduces first article setup time. Overlay CAD and/or Gerber data and compare:

- Loaded Boards

- Bare Boards

- Stencils

- Components

- Wet Glue / Solder Paste/ Epoxy

First Article Inspection

ScanPLACE increases productivity with the ability to scan the first article and compare it to the Centroid data.