X-ray inspection specialist, SEC Co., Ltd. is pleased to announce that since the launch of its industrial X-ray inspection equipment in October, the company has exceeded 1,500 units in cumulative sales volume. The company successfully developed the only industrial X-ray tube in Korea, and has maintained the No. 1 market share in Korea for many years based on the development of excellent systems suited to specific applications and competitive pricing.

In 2002 SEC Co., Ltd. successfully localized and commercialized industrial X-ray inspection equipment, for which Korea was previously dependent on imports. The company has since built a line-up of more than 20 models through continuous development.

CEO of SEC Co,. Ltd., Jonghyeon Kim said: “Currently, exports are continuously increasing through the operation of overseas subsidiaries and branch offices, as well as agency contracts. The proportion of exports based on sales is 40 percent, and will exceed 60 percent within the next five years and showed a strong will to advance overseas.”

Of the 1,500 units, in-line automated X-ray inspection equipment (hereinafter referred to as the AXI System) sales volume is about 130 units. The demand for the AXI system began in 2010, and since safety accidents have been continuously occurring due to defects in electric components and batteries in automobiles and smart devices for the last five years, companies are striving to improve quality and reliability by conducting total inspection using the AXI System. Due to this, the sales ratio of SEC Co., Ltd., based on the total number of units sold, has increased from five to ten percent per annum in the past, but is now at 20percent per annum.

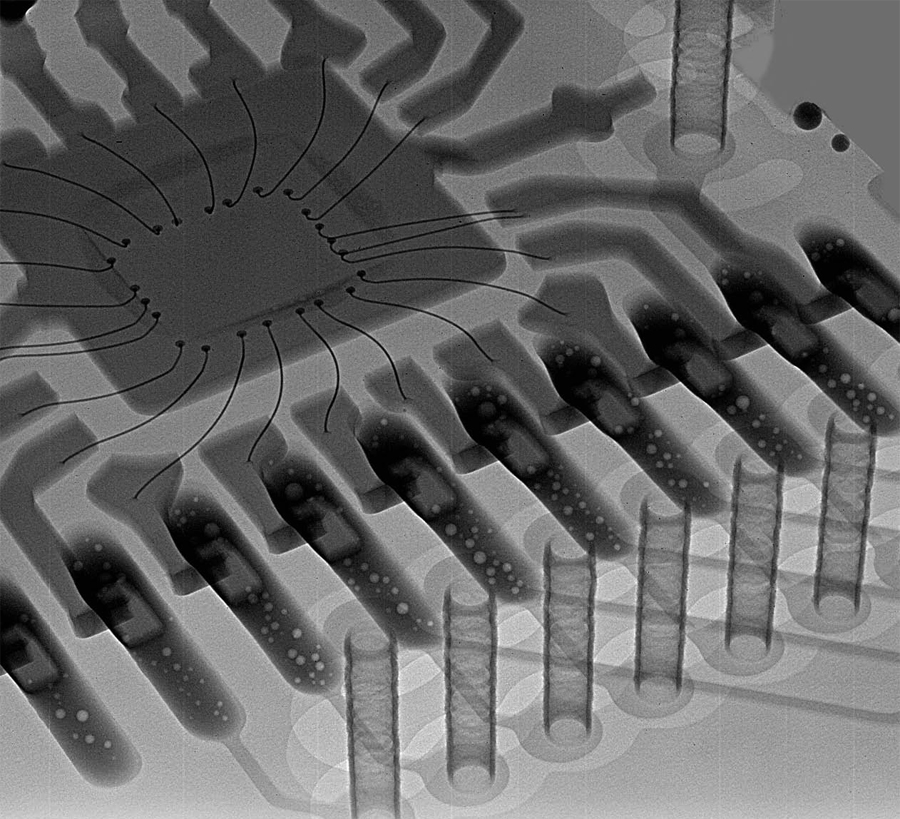

The AXI System, which is the representative system of SEC, comprises X-eye 6200AXI (2D automatic inspection) and X-eye 6300AXI (3D CT automatic inspection). Both models are 4-high AXI systems and offer tremendous cost benefits for maintenance, high resolution, high accuracy and reliability, and high speed, and it is a technology possessed only by SEC Co., Ltd. X-eye 6200 can be used to inspect bonding wire, BGAs, Micro-bumps, QFNs, QFPs, electronic components of automotive and batteries, etc., and X-eye 6300 can be used to inspect iGBTs, BGAs, micro-bumps, QFNs, QFPs, electronic components of automotive and sensors, etc. More information can be found on YouTube (https://youtu.be/u_NJbsuqJpk).

SEC’s X-ray equipment is currently used in the final manufacturing stage for semiconductors and smartphone batteries.

About SEC

SEC is a leading inspection equipment provider, providing industrial X-ray inspection systems and Scanning Electron Microscopes. Established in 1991, with almost 30 years of technical know-how, SEC is continuously developing the backbone of e-beam inspection equipment in Korea. For more information, visit http://www.seceng.co.kr/eng.