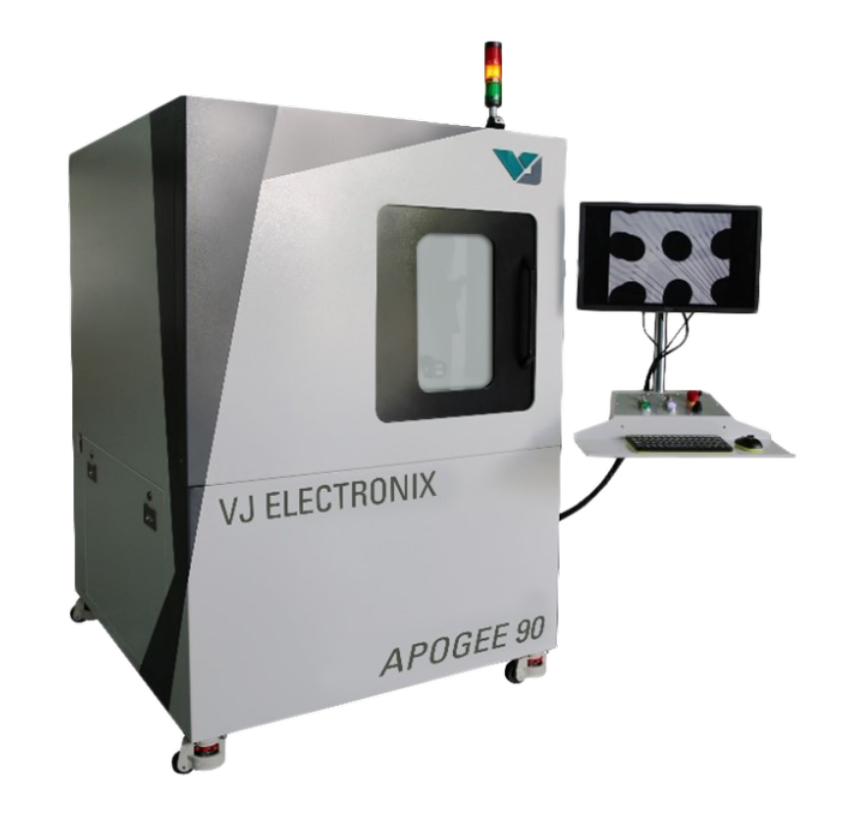

Microfocus X-ray Inspection System – Apogee 90

- Category: X-Ray Inspection Systems

- Manufacturer: VJ Electronix

X-ray Inspection of Printed Circuit Boards, Components, and Assemblies

Optimal performance and operability at a fraction of the cost of comparable x-ray inspection systems

About the Microfocus X-ray Inspection System – Apogee 90

The APOGEE 90 was built to fullfill the need for an affordable and reliable inspection system with advanced features for defect detection, failure analysis, and NDT in production environments. The system is capable of capturing the highest clarity 2D & 2.5D x-ray images that provide operators with confidence in their findings.

Equipped with powerful and versatile Vi3 Software, the APOGEE 90 creates efficiency in almost any inspection task - from quick spot checking of random samples and automated inspection routines, to enhanced analysis of BGAs and QFNs and more. Operators can easily navigate the intuitive GUI and perform tasks with minimal training.

Creatively designed with the superior resolution and automation typically found in higher cost systems, the APOGEE 90 is one of the most powerful and economical, maintenance-free x-ray inspection systems available today.

KEY BENEFITS:

- Highest Clarity Images for Defect Detection, Failure Analysis, and NDT in Production Environments - Even at Micro-scale.

- Visualization of the Most Challenging PCB Assemblies with Complete Confidence in the Results

- Optimal Performance and Operability at a Fraction of the Cost of Comparable X-ray Inspection Systems

- Powerful and Versatile Software Creates Efficiency in Almost Any Inspection Task

KEY FEATURES:

- Powerful 90kV Sealed Microfocus X-ray Tube

- 4µm Focal Spot

- Oblique Angle Inspection up to 45°

- High Resolution 5” Digital Flat Panel Detector

- 6-Axis Motion Control

- Programable Automated Inspection Sequences

- Valuable Image Enhancement & Processing Tools (ie. Averaging, Contrast, Exposure, 9x Filters, Pseudo3D)

- Real-time Image Visualization & Image Capture