Large Format Fully Automatic Screen Printer | JUKI PMAXII

- Category: SMT Stencil Printers

- Manufacturer: juki

Perfect for long LED PCBs

Print up to 1,220mm x 800mm

The PMAXII printers utilize a patented mathematical calculating algorithm to ensure the machine’s high accuracy print alignment that easily achieves 01005 (0402 metric) printing.

About the Large Format Fully Automatic Screen Printer | JUKI PMAXII

- PCB Size Range: Max. 1220mm (L) x 800mm (W)

- Stencil Size Range: Min: 737mm (L) x 737mm (W) | Max: 1300mm (L) x 850mm (W)

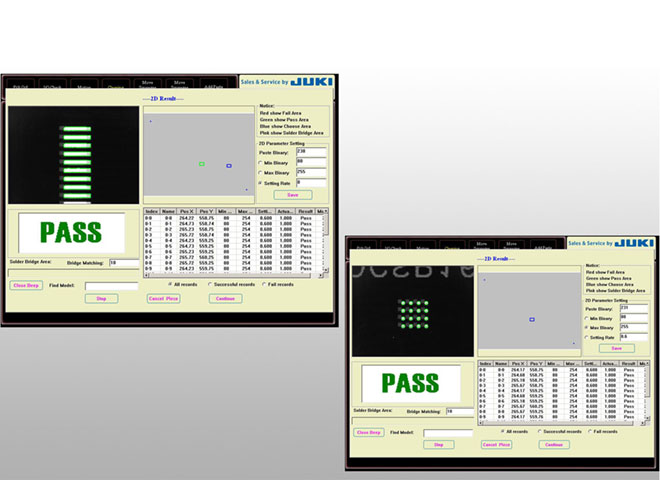

- Paste Inspection: Automatic 2D (standard)

- Weight: Approx. 1800kg

- Vision and Optics System

- Automatic PCB Thickness Control

- Individual front/rear, Self-Adjusting, Motorized Programmable Floating Print Heads

- Wiper System

- Lift Table

Motorized Front and Rear Squeegees - Designed to meet the need of different pressures on the front and rear squeegees, each can be programmed independently while the functionality of self leveling prevents solder paste leakage. Various snap-off modes can also be selected to accommodate all types of PCB's and paste.

Patented PCB "Flexible Auto Clamp" (FAC) System - The conveyor system includes a built in PCB snugger (side clamp) and top clamp system. Changing between each requires no change of hardware and is controlled by a simple mouse click.

Wiper System - The stencil cleaning has 3 modes: Wet, Dry, Vacuum. Each mode can be programmed individually or combined in any way. If auto cleaning is not necessary, the system allows manual cleaning within its operation menu, which shortens cleaning time and improves production efficiency.

2D Solder Paste Inspection System - The 2D paste inspection system can detect excessive/insufficient, presence/absence, and bridging.

Automatic PCB Thickness Control - Uses linear motor drives to perform the dynamic adjustment of the lift table. This superfine motion and lock mechanism maintains higher precision during the printing process.

Lift Table - Solid Cast Lift Table designed to meet the rigors and demands of a 7x24 manufacturing environment

Available Options:

- TUV/UL Certi cation

- Stencil inspection function

- Closed loop feed back with SPI systems

- APD (automatic paste replenish) system

- Magna Print squeegee blades

- Larger FOV camera (21mm x 16mm)

- Automated underside PCB support