Large Area Ultrasonic Coating System – FlexiCoat MAX

- Category: Photoresist & Polyimide Films Coating Systems for Photolithography

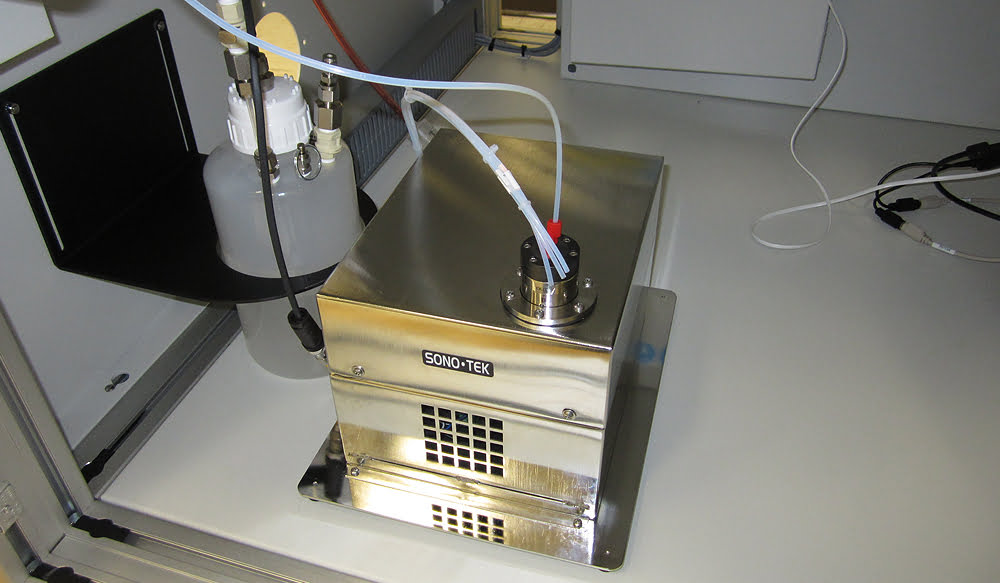

- Manufacturer: Sonotek

Large area, fully automated, programmable standalone system with coordinated XYZ motion control using Windows-based software and user-friendly teach pendant with trackball. Versatile mid to high-volume or pilot scale production thin film coatings.

About the Large Area Ultrasonic Coating System – FlexiCoat MAX

Basic Specifications

| Dimensions: Varies |

| Work Area*: |

| Control: Windows-based (PC included) |

| Power Requirements: 120V, 220V +/- 10%, 50-60 Hz |

| Air: 551.6 kPa (80 PSI) dry unlubricated air |

| Motors: Servo |

| Certification: CE |

| Ultrasonic Nozzle Designs: AccuMist, Impact, Vortex, MicroMist, or Propel |

Options:

| Heat and/or Vacuum Plate: 150C |

| Head configuration: up to 3 heads (Ultrasonic or Vector) |

| Common Options: wire/rod coater, Nozzle rotate and/or tilt, 1 or 2 drawer load system, LEL Sensors, cleanroom upgrade, aggressive material upgrade, Auto substrate flipping, IR heat |

| Liquid Delivery: Common Liquid Delivery: Syringe pump (standard, Sonic or stirring), gantry mounted syringe pump, MicroFlow, SonoFlow Fusion, HyperFlow catalyst pump, gear pump |

| *Additional custom options may be available depending upon application requirements |