SMT Production Software

- Category: JUKI Accessories & Software

- Manufacturer: juki

Software For Optimizing SMT Production

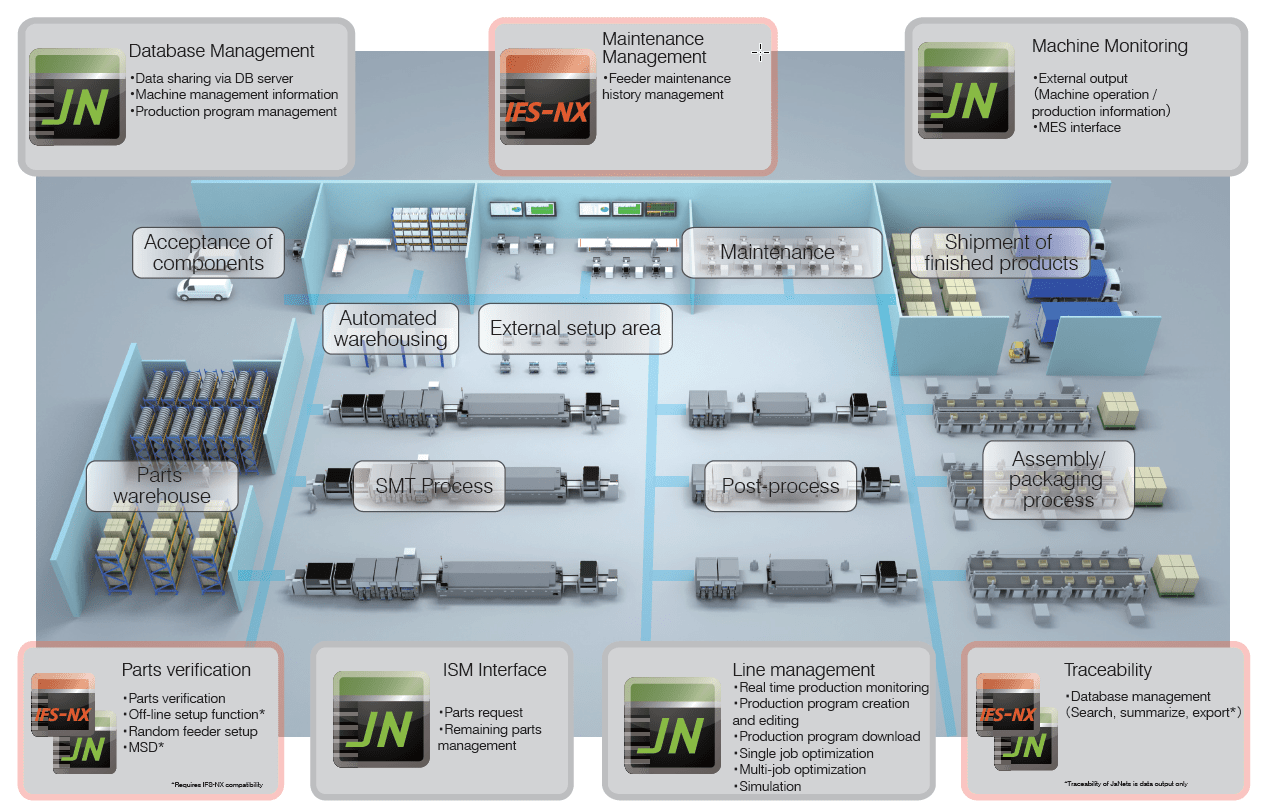

JUKI’s SOFTWARE SOLUTION increases productivity within the SMT production. A modular software concept allows you to focus on individal costumer requirements. Thanks to the supplied controlling data, production processes can be better interconnected with each other therefore continuously enhancing the overall performance.

About the SMT Production Software

The provided software by JUKI encompasses individual modules for programme and production preparation, for the conversion of production data as well as for the optimisation of the complete production line - regardless of whether one is operating a single machine, a complete SMD production line or several lines. The software has a modular structure and is available in different licensing models to allow the greatest possible flexibility.

JUKI SOFTWARE MODULES:

JUKI Advanced Network System – JaNets

JUKI Advanced Network System optimises the overall production of the automatic SMT line. It supports the preparation of programmes offline at a separate workplace (client PC) and also delivers production programmes to any machine operating within the line and administers all the data at the same time. Data for the control of each machine as well as for management of the complete production line, are collected and consolidated. Subsequent EDP systems such as enterprise resource planning systems can be connected with an optional, external export function. It is possible to export the following data (in JSON format):

- Placement Rate

- Machine Configuration

- Number of Components

JUKI Intelligent Shopfloor Solution – IS

JUKI Intelligent Shopfloor Solution is a modular administration software (for Server or Client) concentrating on the SMT production line and equipped with all the necessary functions. It supports several users, for example several lines, integrated intelligent feeders and traceability. JUKI IS supports the import of CAD software data, the set-up of placement programmes with automatic completion of the components database right up until the download of the suitable programme into the line. Changes regarding a placement programme are automatically recorded.

JUKI Intelligent Shopfloor Solution Server – IS Server

JUKI IS Server supports the construction of production programmes offline at a separte workplace (client PC) as well as the control of a complete line (a programme is automatically sent to the SMT production line). JUKI IS Server makes it possible to exchange production programmes between the lines and includes a Client- / Server-Architecture with a central database.

JUKI Flexline CAD

JUKI Flexline CAD is a data conversion programme to convert text files that are produced from CAD systems or come from third-party machines and are modified into a JUKI compatible data format.

JUKI Intelligent Feeder System – IFS

JUKI Intelligent Feeder System minimizes the time for feeder setup and delivers a large degree of control over material flow as well as over the complete SMT production line processes.

Compared to other intelligent feeder systems, IFS considerably exceeds the principle of controlling the ordinary placement machine because it is based on a patented RFID technology. Feeder intelligence is therefore available

- directly on the machine

- outside the machine

- on decoupled trolleys and

- on storage carts.

All feeders and their assigned components are always visible – independent from their current position in the SMT production process. Making full Traceability – on process and material – available at all time. Every production material is easily identified, traced and controlled in any location of the SMT production. To avoid unnecessary barcode scans, IFS database seamlessly cooperates with other systems such as MES – Manufacturing Execution System – and ERP – Enterprise Resource Planning.

IFS provides the foundation to enable Industry 4.0 throughout the manufacturing floor. It can be expanded in a modular and scalable manner to support a wide variety of options, including the following:

- Connectivity – Cogiscan’s Co-NECT platform enables seamless data exchange with non-Juki ecosystems, including capital equipment from other suppliers, as well as enterprise SW systems (ERP, MES, PLM).

- Material Control – Storage Tower TTC, Kitting Control, MSD control, LCR Control.

- Traceability – Complete product traceability, from Components and Materials, to Process, and Box-Build (Genealogy).

- Analytics – Real time KPI/OEE dashboard and Historical Analytics (Factory Intelligence)

- Track-Trace-Control (TTC) for Juki’s Complete Line Solutions – including TTC for Juki Screen Printers, SPI, Placement, Reflow, & AOI machines.