Inline Selective Soldering Machine – FLEX-i2

- Category: Compact Inline Selective Soldering Machines

- Manufacturer: SASinno

Highest Flexibility, Compact In-Line Selective Soldering Machine

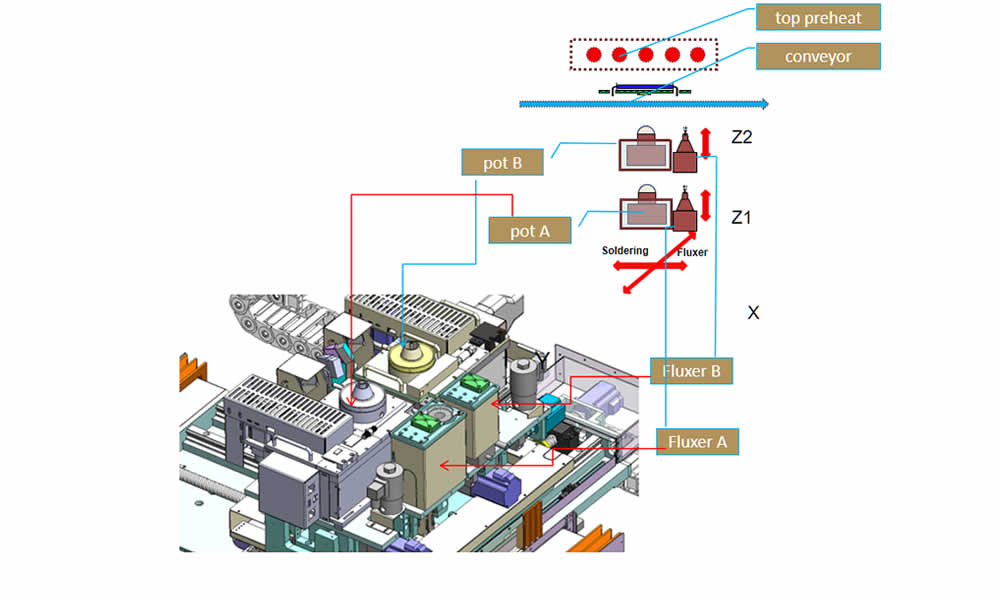

PCB will be moved with stainless steel wheels conveyor system. After it’s stopped by stopper, it will be side clamped by rear clamper cylinder, then the spray fluxer will start to work under setting program, after that the same table will move x,y,z1,z2 to move different solder pot under PCB for selective soldering. During whole process, the top preheater can be on to help keep the PCB’s temperature.

About the Inline Selective Soldering Machine – FLEX-i2

- 1 drop jet fluxer as standard, with an optional extra

- Bottom IR preheating & top preheating zone

- 2 solder pots in individual Z-axis

- One section conveyor

- Fixed PCB conveyor with moving solder pot/fluxer

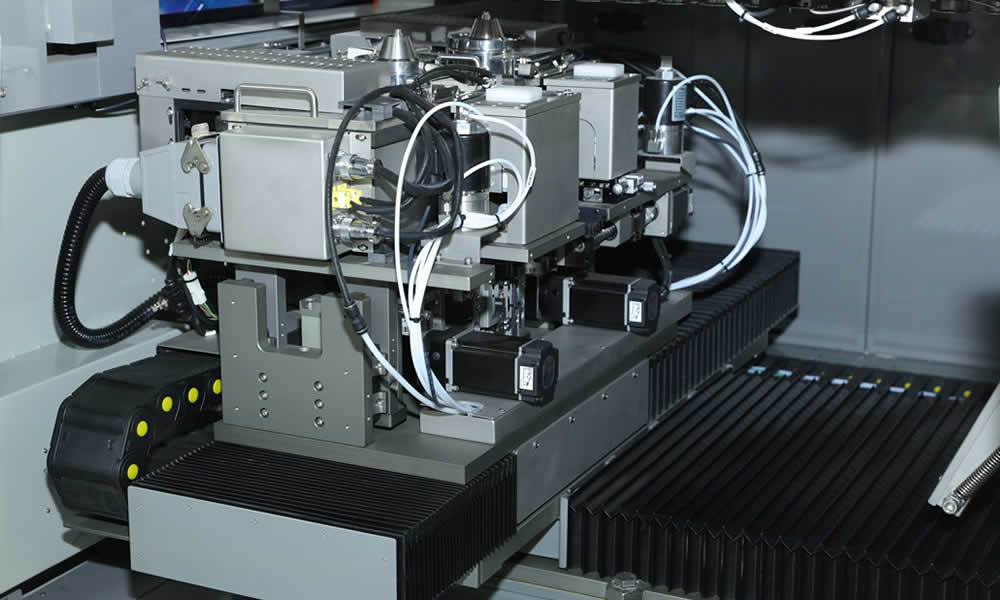

- 4-axis full servo drive with ball screw movement

- Solder pot and fluxer share XY motion table

- All-in-one flux, preheating & soldering

- Windows 10 system

- Standard equipped with wave height calibration

- Real-time soldering process monitor

Specifications

| General | |

|---|---|

| Operating power/Max power | 6KW/16KW |

| PCB dimension | Min50x50---Max PCB W457.2 x L508mm (18" x 20") (Two nozzle solder individually) Max PCB W508 x L508mm (20" x 20") (Two nozzle solder parallel) |

| Machine dimension | 1420(L)*1725(W)*1700(H) |

| Net weight | 900KG |

| Power supply | 3PH 380V 50HZ |

| Air supply | 3-5 bars |

| Exhausting required | 800M3/h |

| PC | Yes |

| Typical Program Time | 10 Minutes |

| PCB Robotic Platform | |

| Flux Nozzle Type | drop jet fluxer made in Germany |

| Flux Nozzle Quantity | Standard equip 1 set, optional to equip another set |

| Flux Tank Capacity | 1L |

| Flux Tank Quantity | Standard equip 1 set, optional to equip another set (when use two different flux) |

| Preheat | |

| Preheating method | Top IR preheat,option with bottom preheat |

| Solder Management | |

| Solder pot type | Standard equipped with mechanical pump, optional with electromagnetic pump (made in Germany) |

| Standard Solder Stations | 2 |

| Solder Pot Capacity | 15 kgs |

| Solder Temperature Control | PID |

| Heat-Up Time | About 40mins |

| Max Temperature | 350 ℃ |

| Mini Wave Nozzles | 3 to 12mm |

| Customized nozzle | Available |

| Axes of Motion | X, Y, Z1, Z2 |

| Position Accuracy | + / - 0.05mm |

| (N2) Inertion Management | |

| N2 Consumption per Nozzle | 4m3/H |

| Required N2 Purity | >99.99% |