Compact Inline Selective Soldering Machine – Unit-i1

- Category: Compact Inline Selective Soldering Machines

- Manufacturer: SASinno

All-In-One Compact Inline Selective Soldering Machine

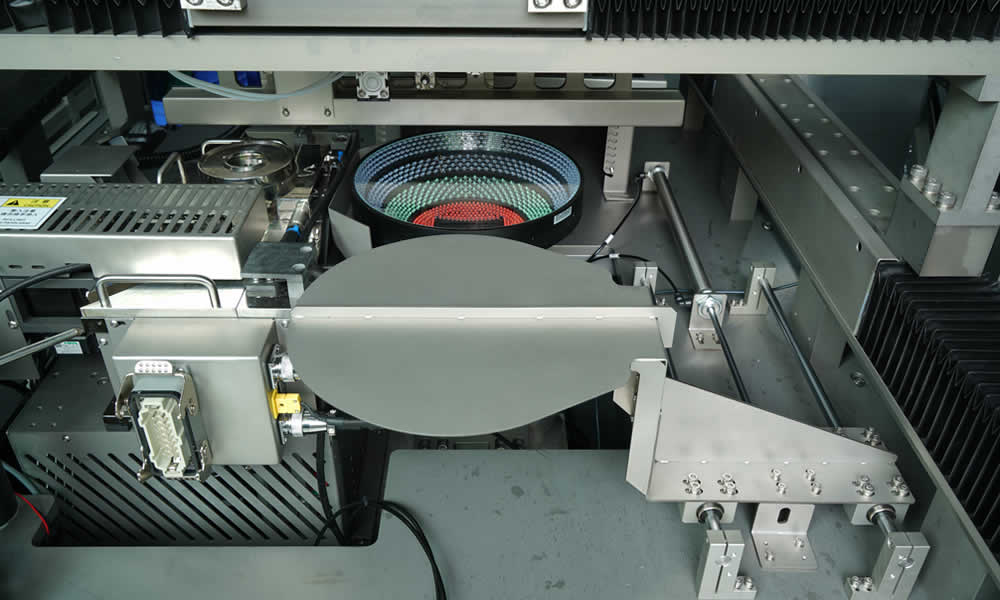

It combines a drop jet fluxer nozzle, bottom IR preheating, selective solder pot and AOI function. The result is a full-function station for fluxing, preheating, soldering, and inspection.

About the Compact Inline Selective Soldering Machine – Unit-i1

After soldering is complete, the built-in AOI inspects all of the soldered joints for bridging, too little solder, excessive solder, solder particles, etc. Additionally, the "auto repairing function" can be activated to solder the "defect" position again automatically.

Unit-i1 can be used as standalone or as a module with the highest flexibility. For volume production, customers can place unlimited boards one after another. For the production of different boards, customers can separate each machine as every machine can work individually.

- 1 drop jet fluxer

- Bottom IR preheating

- One solder pot, with one wave tunnel

- The PCB is moving by a conveyor, the conveyor table movies in X/Y, the solder pot/fluxer movies in Z

- Windows 10 system

- 3-axis full servo drive with ball screw movement

- Standard equipped with wave height calibration

- Real-time soldering process monitor

- Optional built-in AOI inspection function

Specifications

| Item | Unit-i1 |

| General | |

|---|---|

| Operating power/Max power | 4KW/6.5KW |

| Machine dimension | 1318(L)*1600(W)*1246(H) |

| Net weight | 400KG |

| Power supply | 3PH 380V 50HZ Or 1PH 220V |

| Air supply | 3-5 bars |

| Exhausting required | 300M3/h |

| PC | Yes |

| Typical Program Time | 10Minutes |

| Conveyor | |

| PCB dimension | W50 x L50---W350xL450mm |

| PCB Clearance | Top 100mm bottom 30mm |

| PCB Weight | Max 5kg |

| Conveyor width | Auto |

| Conveyor assembling motion | X,Y motion with server motor/driver |

| Fluxing | |

| Flux Nozzle Type | Drop jet fluxer |

| Flux Nozzle Quantity | 1 |

| Flux Tank Capacity | 1L |

| Flux Tank Quantity | 1 |

| Preheat | |

| Preheating method | Bottom IR heater |

| Solder Management | |

| Solder pot type | mechanical pump |

| Standard Solder Stations | 1 |

| Solder Pot Capacity | 15 kgs |

| Solder Temperature Control | PID |

| Heat-Up Time | About 30mins |

| Max Temperature | 350℃ |

| Wave tunnel | 1pcs |

| Mini Wave Nozzles | Dia 3 to12mm |

| Customized nozzle | Available |

| Axes of Motion | Z |

| (N2) Inertion Management | |

| N2 Consumption per Nozzle | 1.5 m3/H |

| Required N2 Purity | >99.99% |

| AOI Insepection | |

| Camera | 5 mega pixels |

| Resolution | 15µm |

| FOV | 36*30mm |

| Lighting | >RGB 3 color lighting |

| Inspection defects coverage | less solder, excessive solder, bridging etc |