Fully Automated Multi-Axis Ultrasonic Wave Solder Spray Fluxing System

- Category: Fluxing Systems for Wave Solder Machines

- Manufacturer: Sonotek

SelectaFlux Inline X2 Selective Fluxing System for Wave Soldering

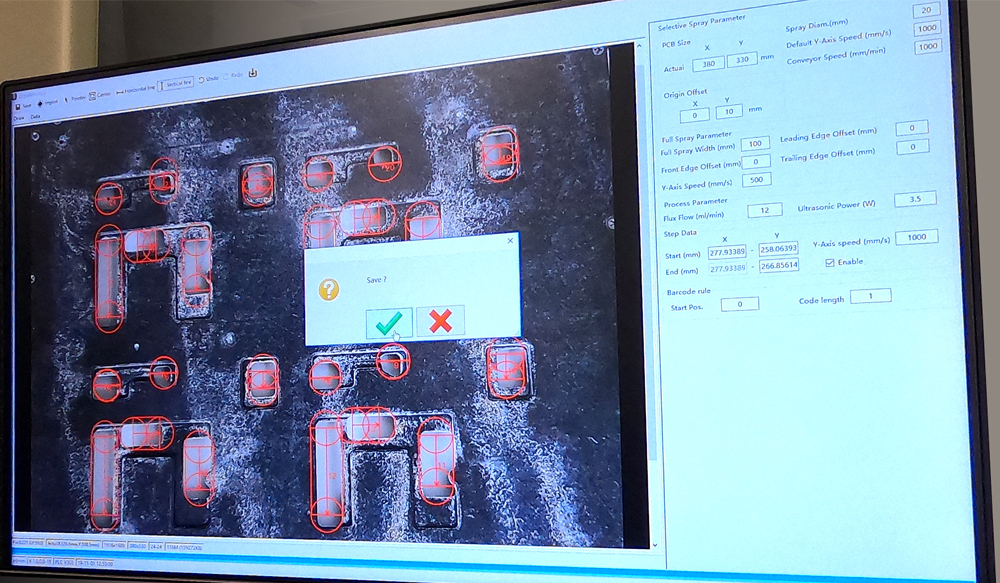

A fully automated multi-axis ultrasonic wave solder spray fluxing system with precision selective area fluxing capability. Advanced point programming capable; just import an image of the PCB and highlight the desired areas to be fluxed. Ideal for pallets and PCB’s with unnecessary areas to be fluxed. Has been proven to reduce flux consumption by up to 93%.

About the Fully Automated Multi-Axis Ultrasonic Wave Solder Spray Fluxing System

Designed for medium to high mix lines, the system has a barcode option allowing the capability to change desired flux areas on the fly. The system is available in a standalone format for easy installation in front of any wave solder machine. Due to the advanced spray precision of the SelectaFlux X2, maintenance is reduced by 95% compared to conventional pressure spray fluxers. All SonoFlux systems feature non-clogging, repeatable, low maintenance ultrasonic spray performance.

Features:

- Compatible with ALL fluxes

- Easily retrofits into all major selective solder machines

- Reduced wasteful overspray and atmospheric contamination

- Minimal servicing and downtime

- Self-cleaning ultrasonic nozzle prevents clogging

- Controlled -velocity will not harm or disturb components while giving maximum top side fill

- Spray pattern adjustable from 2 mm - 38 mm (0.080" - 1.50")

- Wide range of delivery rates from 1 - 250 microliters/second

- Also ideal for tinning and odd-shaped components

Complete System Includes:

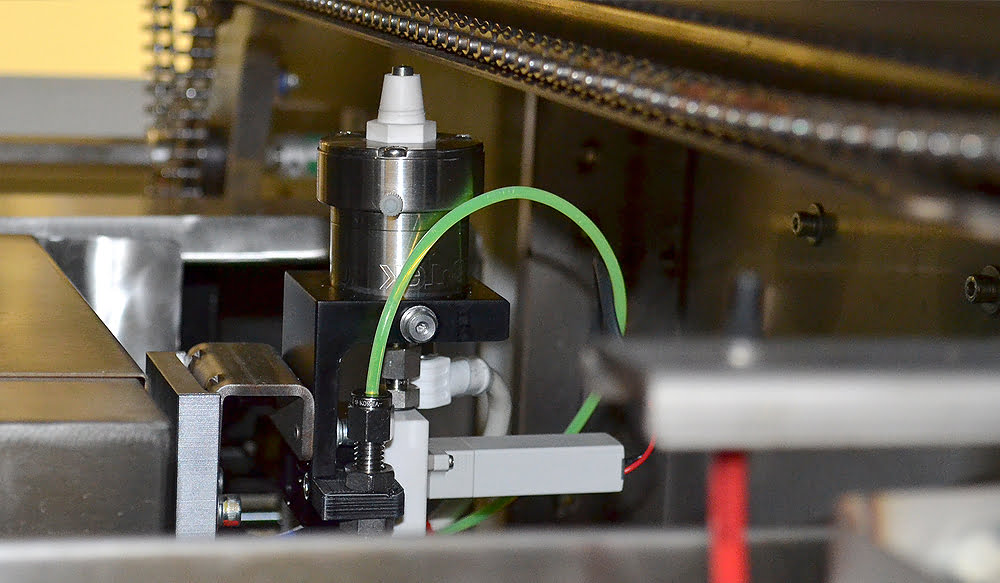

- Ultrasonic nozzle with focus-adjustable air shroud

- Broadband ultrasonic nozzle generator

- Electrical and I/O connections

Operating Principle

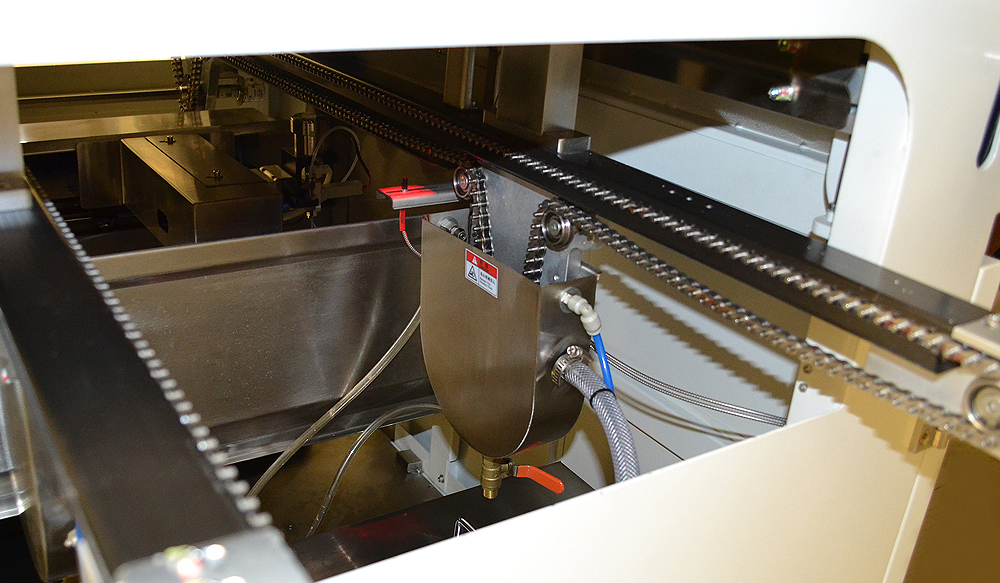

The SelectaFlux system is a complete,ready-to-integrate selective fluxing system with customer-supplied liquid delivery. It combines Sono-Tek's unique Microspray ultrasonic atomizing nozzle with low pressure air to produce a controlled,highly focused beam of spray. A separate control module handles input/output system functions.

Compressed air, typically at 1 psi, is introduced into the diffusion chamber of the air shroud,which produces a uniformly distributed flow of air around the nozzle stem.

The ultrasonically produced spray at the tip of the stem is immediately entrained in the air stream.An adjustable focusing mechanism on the air shroud allows complete control of spray width.

The spray envelope is bow-shaped. The width of the bow is controlled by moving the focus-adjust mechanism in and out. The distance between nozzle and substrate can be varied from near-contact to approximately two inches.

Basic Specifications

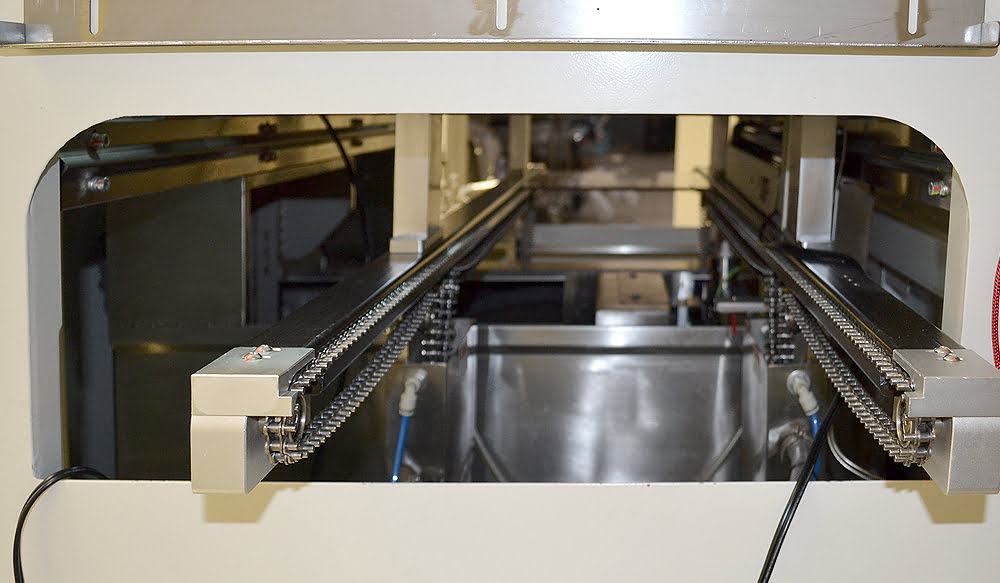

| PCB Size: Min: L120 mm W60 mm, Max: L550 mm W450 mm |

| Conveyor Speed: 300-1000 mm/min |

| Width Adjustment: 50-450 mm |

| Flux Tank: 5 Gallon stainless steel flux tank with level sensor |

| User Interface: PC/Windows® 10 |

| Programming: Image Import of PCB and highlight area for fluxing |

| Power requirements: 220VAC, 50/60 Hz, 1kW, +/- 10% |

| Machine Dimensions: 1520 mm L x 1250 mm W x 1820 mm H |

OPTIONS:

Bar code reader