Photoresist Deposition System

- Categories: Ultrasonic Spray Coating of Photoresist for MEMS Wafers, Photoresist & Polyimide Films Coating Systems for Photolithography

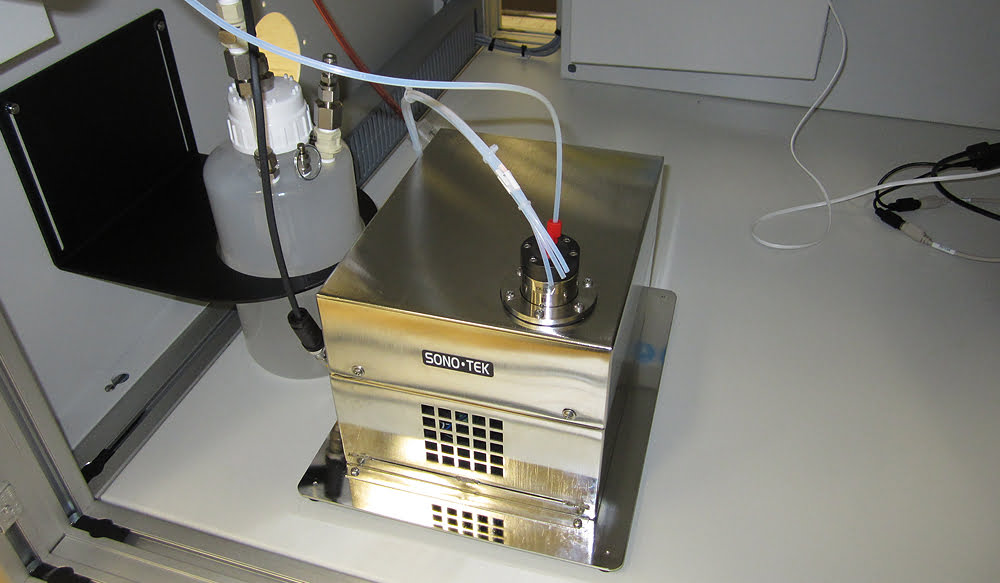

- Manufacturer: Sonotek

SPT200 – Programmable Standalone XYZ Coating System For Photoresist Deposition.

A full solution for coating semiconductor wafers with uniform thin films of photoresist in applications where traditional high speed spin coating cannot provide uniform coverage of deep well topographies or high aspect ratios such as MEMS. Designed for 100, 150, 200, and 300mm (option) semiconductor wafer processing.

- Precise substrate uniformity and process repeatability

- Integrated wafer lockdown

- Full process control with Windows®-based programming software

- Precise temp control

- Excellent for semiconductor MEMs photoresist applications

About the Photoresist Deposition System

Ultrasonic spray deposition of photoresist onto MEMS and other precision semiconductor wafers with high aspect ratio features and complex 3-dimensional structures. The SPT200 is an alternative to high speed spin coating, which is often unable to provide uniform coverage of deep trenches.

Basic Specifications

| Dimensions: 1066mm W x 1765 mm H x 1095 mm D (42” W x 70” H x 43” D) |

| Work Area: 465 mm x 465 mm x 100 mm (19.7” x 19.7” x 3.9”) |

| Control: Windows-based (pc included 19-inch touch screen interface) |

| Power Requirements: 208-240VACc, 16A max, 50/60 Hz 1 phase (L,N,G) or (L1, L2, G) |

| Air: 551.6 kPa (80PSI) 1 compressed air, 1 nitrogen |

| Motors: Brushless DC Servo |

| Certification: CE |

| Ultrasonic Nozzle Designs: Vortex, AccuMist, Impact |

Options:

| Heat and/or Vacuum Plate: Standard Option |

| Head configuration: Up to two heads |

| Liquid Delivery: Common Liquid Delivery: Syringe pump (standard, Sonic or stirring), MicroFlow, SonoFlow Fusion |