Explorer™ one

- Category: Uncategorized

- Manufacturer:

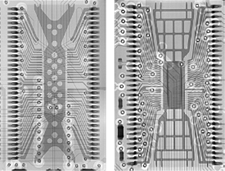

Explorer™ one enables you to quickly understand the quality of your product before it leaves the factory.

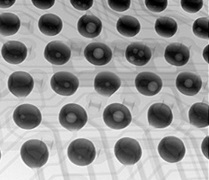

Detect a wide range of manufacturing defects including BGA, QFN and IGBT attachment, PTH filling, cable and connector quality and counterfeit component screening.

About the Explorer™ one

Find defects fast

- See defects as small as 2 μm with QuadraNT® X-ray tube technology. 2 μm is the difference between detecting a bond wire is present, and seeing it in high detail.

- Powerful automated inspection routines save significant time for batches of boards. Program a routine once, then simply click to go.

Easy to use

- Gensys® inspection software, developed for Quadra® Series X-ray inspection systems enables operators and occasional users to perform quality inspection quickly, easily and with minimal training

- Real-time image feedback from our proprietary AspireFP® detector allows you to easily navigate samples and identify defects quickly.

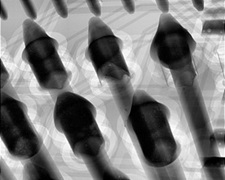

- Easily ensure IPC-A-610 and IPC-7095 compliance with in-built tools for dimension measurement, BGA void analysis, bump diameter and roundness and through hole filling.

Super Compact Footprint

- The perfect balance of board size and system footprint.

- Small footprint makes siting and installation fast and easy.

- Inspecting boards from every side is important to catch head in pillow defects, observe component cracking and to clearly see PTH solder fill level. Our unique double oblique detector geometry inspects 300 x 300 mm boards from every side without requiring a size restricting rotation table.

Explorer one introduces EnviroShield™ Technology, our propriety (patent pending) lead free X-ray shielding technology which is non-toxic and easy to dispose of at end of life. We hope EnviroShield in Explorer one will help us divert hundreds of tonnes of lead from being used in the future.

|  |  |

| X-ray images of 2 identical packages which have been built by different manufacturers | Oblique angle viewing capability shows PTH solder filling | Oblique view shows pad adhesion and reflow quality See head in pillow (HIP) cold joints using oblique angle viewing |