Quadra® 3

- Category: Uncategorized

- Manufacturer:

High quality X-ray inspection for production applications

Quadra™ 3 is your partner for high quality X-ray inspection for production line quality control. Detect a wide range of manufacturing defects including BGA, QFN and IGBT attachment, PTH filling, interfacial voiding, component cracking and counterfeit device screening.

See the finest details

- No compromises. Quadra’s unique double angle geometry lets you look from every angle without a rotation table. You are not limited to rotating smaller samples only.

- See the clearest images of electronics samples. Quadra 3 is the only 0.95 µm system with an image chain completely designed and manufactured in house for electronics samples.

About the Quadra® 3

Simplicity as Standard- The perfect walk-up inspection station. Gensys control software takes high quality images with only a few intuitive mouse clicks, operators can be up and running fast and with minimal training.

- Save time with AIR automatic inspection routines. Teach Quadra once then let AIR automatically inspect for you.

- Minimize downtime. The QuadraNT X-ray tube requires no regular maintenance or filament changes.

- Lifetime repeatability as standard. Since the filament is never changed, inspection imagery is clear and repeatable, today, tomorrow and year after year.

- Oil free. QuadraNT uses an oil free ion pump to maintain vacuum which never requires an oil change.

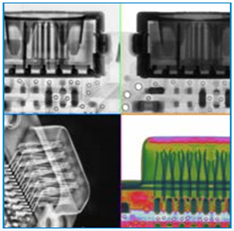

| Easily ensure IPC compliance with automatic measurement and voiding analysis that gives clear pass/fail results. | 4-way split screen view makes identification and comparison easy. | Head-in-Pillow and open joints (see blue circle) effortlessly identified using X-Plane® |