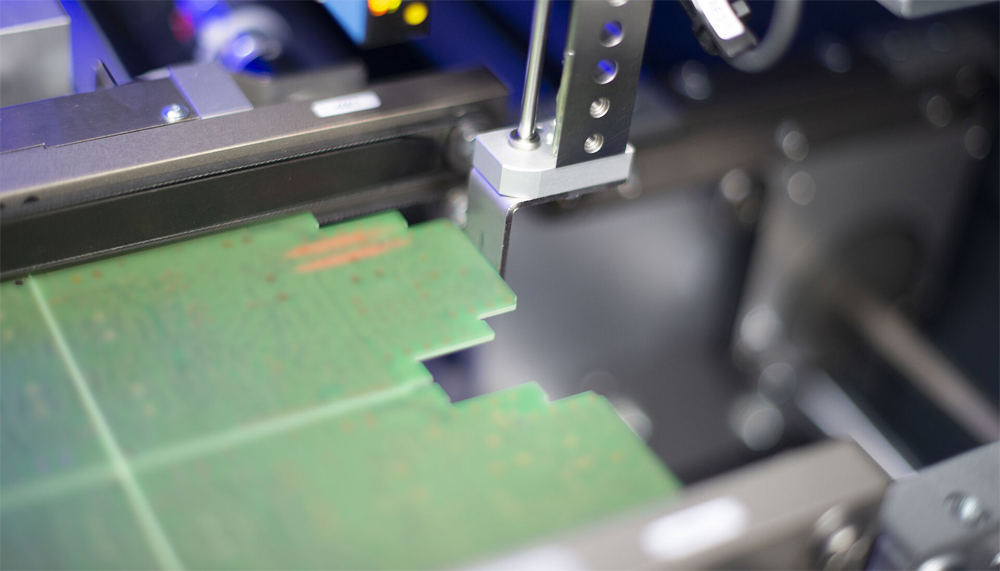

When PCBs vary from the standard, the stopper sometimes has to be repositioned. INSIGNUM laser marking systems perform this process automatically thanks to the “Flying Stopper”.

To get the perfect position for marking, the board must be reliably positioned. Cut outs at the side edges and slots sometimes require a repositioning of the stopper. “Flying Stopper”, one of our hidden champions of the INSIGNUM laser marking systems 4000 and 6000, takes over this process automatically. Via the SIMPLEX interface, the stopper can be individually adjusted in the Y-direction and can therefore react flexibly to any product. Product changeover is accelerated, operator intervention is eliminated. With an integrated flip station, the PCB is stopped exactly in the middle by the Flying Stopper and maintains the optimum marking position even after turning. This saves valuable cycle times