MIRTEC, ‘The Global Leader in Inspection Technology,’ is pleased to announce its participation in the 2021 IPC APEX Virtual EXPO, scheduled to take place March 9-11, 2021 online at www.ipcapexexpo.org.

“We are looking forward to participating in the IPC APEX Virtual EXPO,” stated Brian D’Amico, President of MIRTEC’s North American Sales and Service Division. “MIRTEC will feature video feed and information about our award-winning inspection solutions specifically designed to address the full spectrum of inspec- tion requirements associated with the Electronics Manufacturing Industry.”

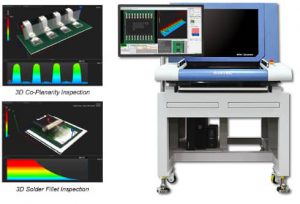

MIRTEC’s MV-6 OMNI 3D AOI Machine is configured with our exclusive OMNI-VISION® 3D Inspection Technology which combines 15 Mega Pixel CoaXPress Camera Technology with MIRTEC’s revolutionary Digital Tri-Frequency Moiré 3D system in a cost-effective platform. MIRTEC’s 15 Mega Pixel CoaXPress Vision System is a proprietary camera system designed and manufactured by MIRTEC for use with our complete product range of 3D inspection systems. MIRTEC’s Twelve (12) projection Digital Tri-Frequency Moiré Technology provides true 3D inspection to yield precise height measurement data used to detect lifted component and lifted lead defects as well as solder volume post reflow. Fully configured the MIRTEC MV-6 OMNI machines feature four (4) 10 Mega Pixel Side-View Cameras in addition to the 15 Mega Pixel Top-Down Camera. There is little doubt that this new technology has set the standard by which all other inspection equipment is measured.

MIRTEC’s MV-6 OMNI 3D AOI Machine is configured with our exclusive OMNI-VISION® 3D Inspection Technology which combines 15 Mega Pixel CoaXPress Camera Technology with MIRTEC’s revolutionary Digital Tri-Frequency Moiré 3D system in a cost-effective platform. MIRTEC’s 15 Mega Pixel CoaXPress Vision System is a proprietary camera system designed and manufactured by MIRTEC for use with our complete product range of 3D inspection systems. MIRTEC’s Twelve (12) projection Digital Tri-Frequency Moiré Technology provides true 3D inspection to yield precise height measurement data used to detect lifted component and lifted lead defects as well as solder volume post reflow. Fully configured the MIRTEC MV-6 OMNI machines feature four (4) 10 Mega Pixel Side-View Cameras in addition to the 15 Mega Pixel Top-Down Camera. There is little doubt that this new technology has set the standard by which all other inspection equipment is measured.

The MV-3 OMNI Desktop 3D AOI Machine is configured with the same hardware and software as MIRTEC’s in-line OMNI-VISION® 3D Inspection Systems providing 100% compatibility across MIRTEC’s entire 3D AOI product line. These systems feature our exclusive OMNI-VISION® 3D Inspection Technology which combines 15 Mega Pixel CoaXPress Camera Technology with MIRTEC’s revolutionary Digital Tri-Frequency Moiré 3D system in a cost-effective platform. MIRTEC’s 15 Mega Pixel CoaXPress Vision System is a proprietary camera sys- tem designed and manufactured by MIRTEC for use with our complete prod- uct range of 3D inspection systems. MIRTEC’s Twelve (12) projection Digital Tri-Frequency Moiré Technology provides true 3D inspection to yield precise height measurement data used to detect lifted component and lifted lead de- fects as well as solder volume post reflow. Fully configured the MIRTEC MV-6 OMNI machines feature four (4) 10 Mega Pixel Side-View Cameras in addition to the 15 Mega Pixel Top-Down Camera. Without question, the MV-3 OMNI is the most Technologically Advanced Desktop 3D AOI machine in the world!

The MV-3 OMNI Desktop 3D AOI Machine is configured with the same hardware and software as MIRTEC’s in-line OMNI-VISION® 3D Inspection Systems providing 100% compatibility across MIRTEC’s entire 3D AOI product line. These systems feature our exclusive OMNI-VISION® 3D Inspection Technology which combines 15 Mega Pixel CoaXPress Camera Technology with MIRTEC’s revolutionary Digital Tri-Frequency Moiré 3D system in a cost-effective platform. MIRTEC’s 15 Mega Pixel CoaXPress Vision System is a proprietary camera sys- tem designed and manufactured by MIRTEC for use with our complete prod- uct range of 3D inspection systems. MIRTEC’s Twelve (12) projection Digital Tri-Frequency Moiré Technology provides true 3D inspection to yield precise height measurement data used to detect lifted component and lifted lead de- fects as well as solder volume post reflow. Fully configured the MIRTEC MV-6 OMNI machines feature four (4) 10 Mega Pixel Side-View Cameras in addition to the 15 Mega Pixel Top-Down Camera. Without question, the MV-3 OMNI is the most Technologically Advanced Desktop 3D AOI machine in the world!

Smart Inspection Software using AI based on Deep Learning Methodology

MIRTEC’s Automatic Programming Software uses Artificial intelligence based Deep Learning Methodology to minimize human error and standardize the pro- gramming process. This advanced software solution automatically analyzes the PCB architecture and assigns the appropriate part type and process parameters for each SMT device thereby maximizing programming efficiency. Only basic operator training is required to achieve optimal inspection results.

MIRTEC’s ‘Best-in-Class’ Optical Character Recognition (OCR) Technology reduces false calls and improves production process efficiency by automatically restoring and inspecting damaged characters through AI and Deep Learning.

MIRTEC’s ‘Best-in-Class’ Optical Character Recognition (OCR) Technology reduces false calls and improves production process efficiency by automatically restoring and inspecting damaged characters through AI and Deep Learning.

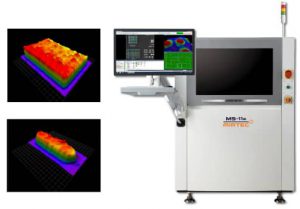

The Award-Winning MS-11e 3D SPI Machine is configured with an exclusive 15 Mega Pixel CoaXPress Camera System, providing enhanced image quality, superior accuracy, and incredibly fast inspection rates.

The machine uses Dual Projection Shadow Free Moiré Phase Shift Imaging, excessive Technology to inspect solder paste depositions on PCBs post screen print for insufficient solder, shape deformity, shift of deposition and bridging.

MIRTEC is Leading the Way to Industry 4.0

MIRTEC’s Total Remote Management System (TRMS) is a fully integrated Indus- try 4.0 Solution which combines remote management with real-time data monitoring and analysis for each system within the SMT production line. MIRTEC’s TRMS provides real-time remote monitoring of status information and statistical data such as equipment operation status, production yield, PC resources, tem- perature, humidity, etc.

The combination of MIRTEC’s 3D Inspection Systems and TRMS provide a vast improvement in production process management. The TRMS Module is a key part of MIRTEC’s Intelligent Factory Automation System, INTELLISYS®. This powerful software suite was designed and developed by MIRTEC to provide manufacturers with a clear view into the manufacturing process, thereby help- ing them achieve higher operating efficiencies and improved quality.

About MIRTEC

MIRTEC is a Leading Global Supplier of Automated Inspection Systems to the Electronics Manufacturing Industry. For further information, please visit www.mirtec.com